Why use tri-axis magnetic sensors ?

Tri-axis Magnetic Sensors

Are you familiar with the term " tri-axis magnetic sensor " ? Although magnetic sensors have a long history and numerous types of magnetic sensors are used around the world, tri-axis magnetic sensors are a relatively new type of magnetic sensor. The major difference between them and other magnetic sensors is that tri-axis magnetic sensors can simultaneously detect three-dimensional magnetic fields along the X-, Y-, and Z-axes, while conventional magnetic sensors can only detect magnetic fields along a single axis.

On this page, we would like to explain the three key features of tri-axis magnetic sensors.

Improved layout flexibility

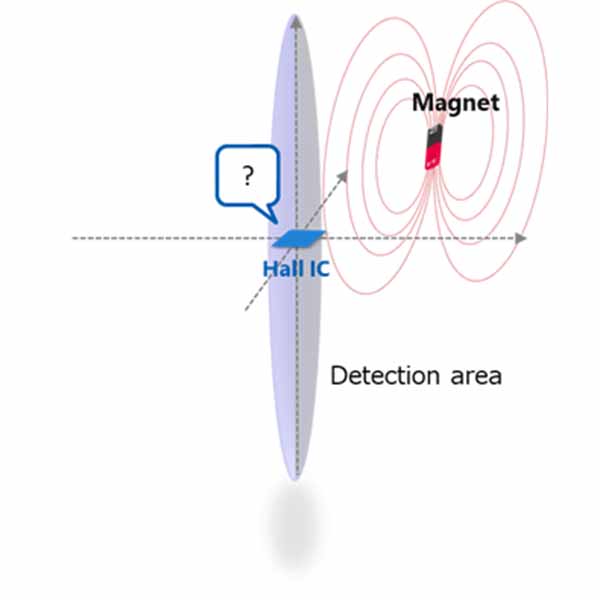

Hall sensors and MR sensors are typical magnetic sensors. Magnetic field sources such as magnets have already been combined with sensors in applications related to movement, such as open/close switches and object movement detection. Component layout is a critical point that must be kept in mind when using magnetic sensors.

In principle, the magnetic sensors described above only detect magnetic fields coming from a specific direction. Therefore, the relationship between the positions of the magnetic field source and the sensor, as well as how the object moves, greatly affect application performance. However, the need to make products more compact and to closely integrate components has made it difficult to optimally arrange sensor and magnetic component layouts. This has led to situations in which target specifications have not been met.

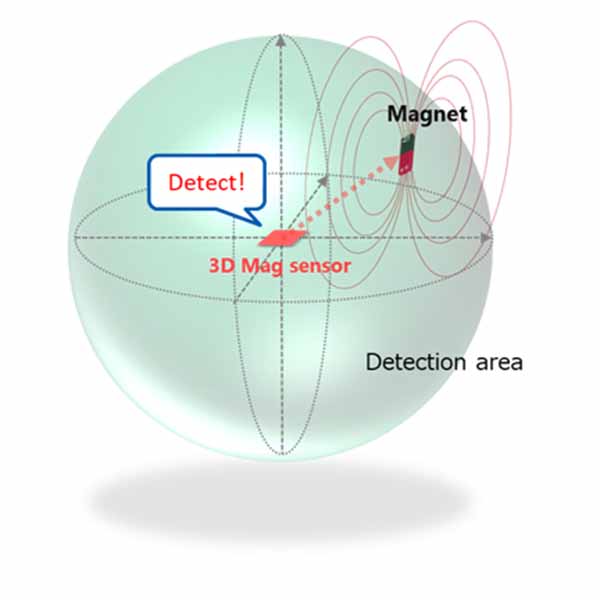

Tri-axis magnetic sensors are directionally independent, so they are capable of detecting magnetic fields coming from any direction. In other words, using a tri-axis magnetic sensor eliminates some of the constraints that apply to sensor/magnet layout and helps improve design flexibility. Similarly, analyzing the data obtained along each axis makes it possible to build systems that are highly resistant to installation positioning variations and other variations.

Conceptual image of increased layout freedom

Detection of complex motion

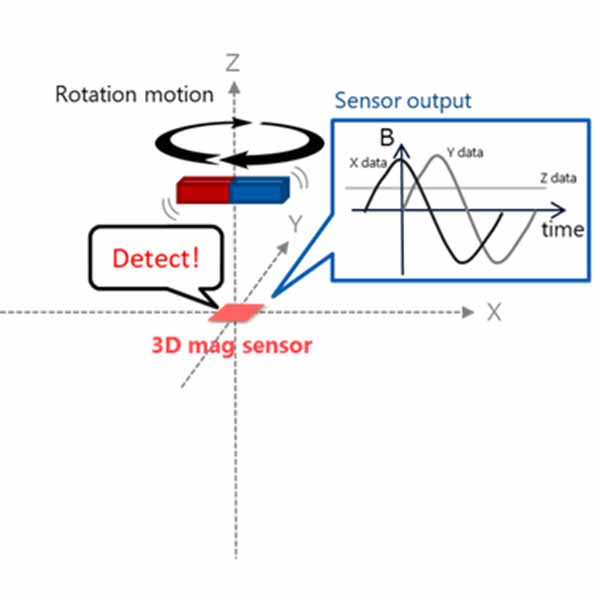

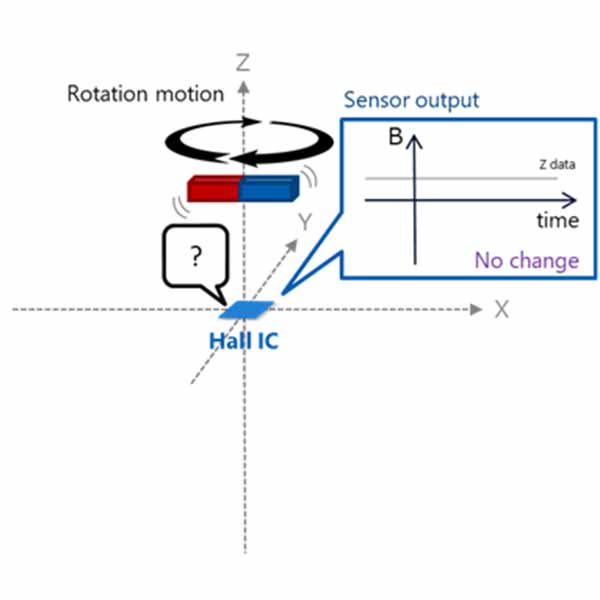

Linear Hall effect ICs are widely used to detect the amount of movement of an object (magnetic body). However, in order for a linear Hall effect IC to accurately detect the amount of movement, the object (or sensor) must move in a straight line. For example, linear Hall effect ICs can precisely detect the movement of a magnet toward or away from the sensor, but cannot detect the movement of a magnet rotating while maintaining the same distance from the sensor. Similarly, they cannot accurately detect the motion of an object moving in three dimensions relative to the sensor.

They are unable to detect complex motion because they are only sensitive along one axis (the Z-axis). As shown in the "improved layout flexibility" item, not only is the magnetic field detection area a small one, but even if an object is placed within the detection area, the linear Hall effect IC cannot detect the motion of an object whose magnetic field does not change with respect to the sensor's axis of detection, such as the rotational motion of the object.

Tri-axis magnetic sensors are magnetically sensitivity along the X-, Y-, and Z-axes, so they do not suffer from the above issues. Tri-axis magnetic sensors are suitable for detecting complex movement.

Example of the change in a magnetic field when a magnetic object rotates

False detection / fraud prevention

One issue that always arises when using magnetic sensors is how to deal with the adverse effects of magnetic fields that are not produced by the moving objects that are to be detected -- so-called "magnetic field disturbances."

The impact of magnetic field disturbances that behave regularly in accordance with conditions envisioned in advance can be reduced through software-based sensor data correction. However, if there are random magnetic field disturbances that vary depending on the usage environment, application performance will be significantly affected.

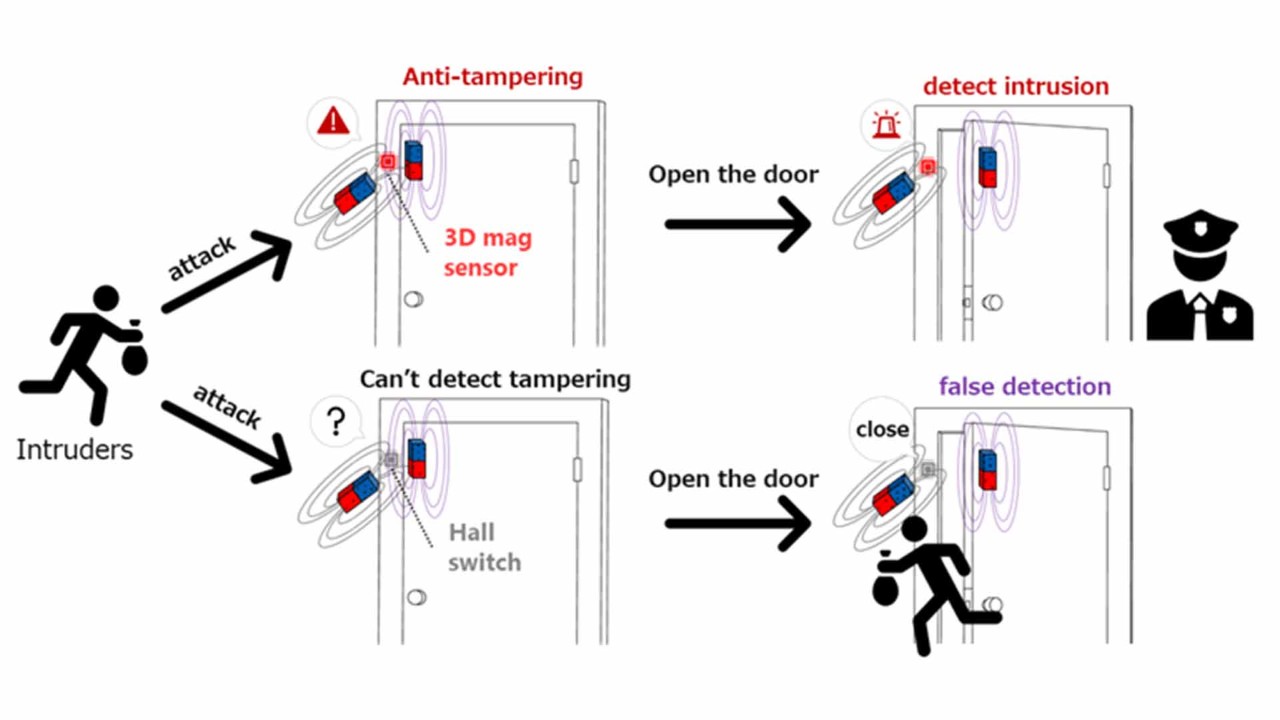

For example, a security product that uses a Hall switch to monitor if a door is opened or closed does so by detecting if the magnetic field applied by the magnet attached to the door exceeds the Hall switch's upper and lower thresholds.

However, since the Hall switch has axial sensitivity only alone one axis, it is impossible to determine whether the applied magnetic field originates from the magnet attached to the door or if it is a magnetic field disturbance produced by another magnetic field source.

In other words, it is physically possible for a malicious actor, such as a thief, to trick the open/close sensor by bringing another magnet closer to the Hall switch and controlling the applied magnetic field.

However, when a 3D magnetic sensor is used, the vectors of the magnetic field applied to the door can be analyzed to distinguish between the magnetic field of the magnet attached to the door and magnetic field disturbances.

In other words, it makes it possible to build a secure door open/close detection system that is resistant to magnetic field disturbances.

Examples of Advantages of Tri-axis Magnetic Sensors in Door Open/Close Detection Applications

Recommend

Solutions

If you would like to know more about how AKM can solve problems, please click below links.

Applications

If you would like to consider proper products from application examples, please click below links.

Products

For more detailed information about each product series, and for selection of specific products, please click below links.