High Efficiency Motor

Development of a motor with high-efficiency and long-lasting

霍尔传感器

Issue ...

Creating a high-efficiency motor.

In recent years, global warming countermeasures have become an urgent issue, and many methods for reducing CO2 emissions are being studied worldwide. 40% to 50% of the electric power generated by emitting CO2 is consumed by motors.

If high-efficiency and long-lasting motors can be made, CO2 can be reduced by reducing power consumption. These types of motors also have advantages for users such as low noise, low vibration, and low heat generation.

* ref. The Japan Electrical Manufacturers' Association (JEMA) "Top runner motor"

Then what is our solution…

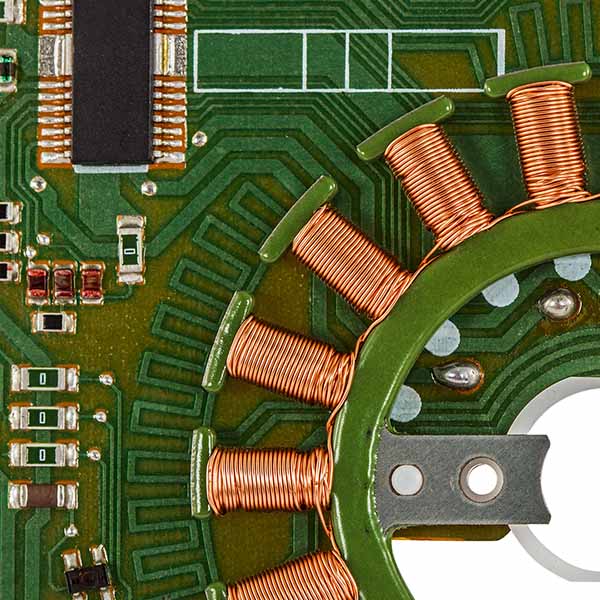

AKM’s Hall elements and Hall effect ICs can make a high-efficiency DC brushless motor.

There are various types of motors in the world. DC brushless motor (DCBL) using Hall elements and Hall effect ICs realizes high-efficiency driving by reducing energy loss due to current switching during rotor rotation.

AKM has been mass-producing Hall elements used in DC brushless motors since 1980, contributing the global reduction of CO2 emissions.

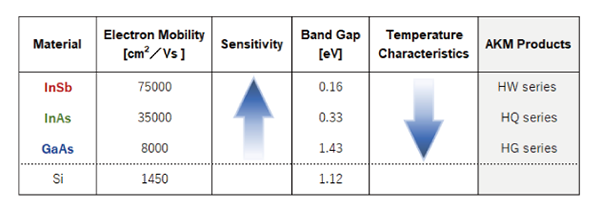

AKM handles all the compound semiconductors that are mass-produced as Hall elements. Using our many years of experience, we can propose the best Hall elements based on material characteristics to meet various needs of customers.

With an extensive product lineup, it can be applied to applications such as precise position measurement and encoders in addition to detection of DC brushless motor rotation.

* Refer to the website below for more information on DCBL motors.

Technical Description

Hall element using a compound semiconductor with high magnetic sensitivity

HW series

(package lineup for applications)

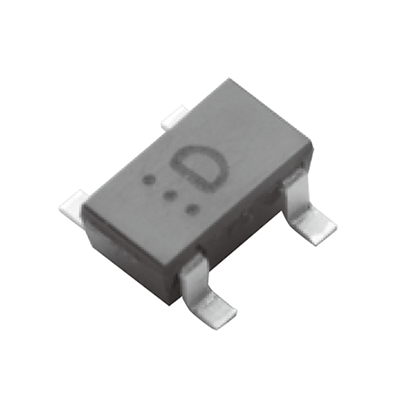

The HW series is a Hall element that can detect magnetic fields with ultra high-sensitivity, enabling accurate detection of magnet rotation, switching the north and south poles. It is used as the suitable sensor for DC brushless motors.

HW101A

HW101A

HW101A4T

HW101A4T

HW102A

HW102A

HW108A

HW108A

HW300B

HW300B

HW322B

HW322B

Hall effect IC for rotation detection

Latch Hall effect IC

(package lineup for applications)

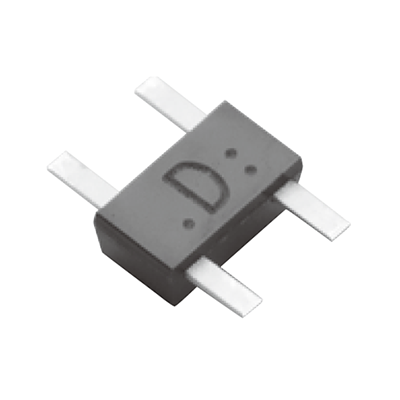

The Hall effect IC is a sensor that processes the output of a Hall element with an internal IC. It outputs High or Low digitally in response to switching of magnetic poles. This eliminates the need for subsequent amplifiers and comparators in the circuit design of the motor, and can be directly received by a microcontroller, enabling circuit design to be simplified.

When a latch Hall effect IC is used for a DC brushless motor, it has the advantage of being less susceptible to noise than a Hall element thanks to the digital output. Hall effect ICs also have a wider temperature range and can be used in harsh environments.

EW610B

EW610B

EW710B

EW710B

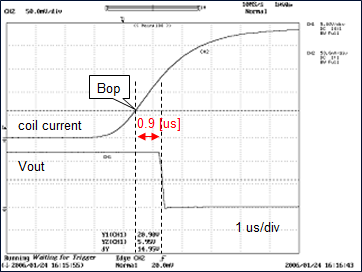

AKM’s Hall effect IC, EW series uses indium antimonide (InSb) as its sensing element. This achieves the fast response speed for Hall effect ICs.

Response speed of EW-610B

Response speed of EW-610B

The EW series is used in DC brushless motors such as electric tools and industrial cooling fans that have large load fluctuations and need to be smoothly rotated from low to high speed.