Simplifying inventory control and downsizing of the system

Rotation Angle Sensors

Issue #05...

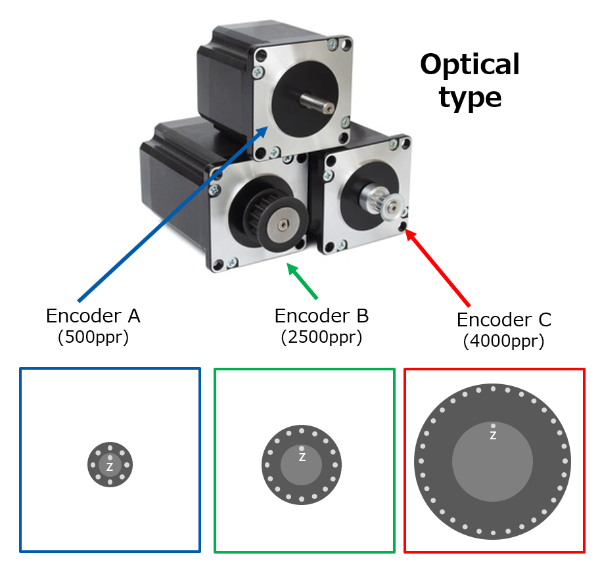

Generally, optical type encoders are required to prepare a slit for each encoder resolution and make a lineup. Also, high-resolution encoders are larger in size due to the increased number of slits.

Are there any encoders with easy inventory management and small-size?

Then what is our solution…

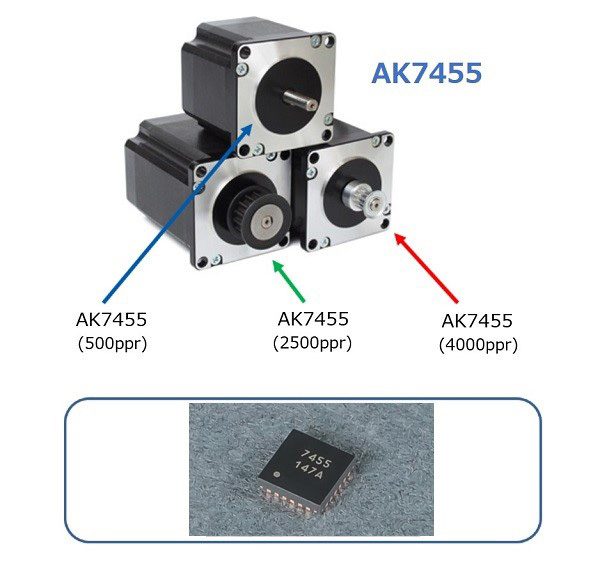

In an optical encoder, the resolution is determined by the number of slits on the disc. If the resolution that required for each application is different, a different encoder need to be provided for each product. In contrast, the AK7455 rotation angle sensor for magnetic encoders is capable of setting various resolutions with one product.

- Simplify parts procurement and inventory control

- Contribute to the standardization of parts in the product lineup

Optical encoder

Optical encoder

AK7455

AK7455

In addition, the use of the AK7455 expands the range of choices when choosing a magnet size or type. And it also contributes to the miniaturization for the whole system.

AKM's magnetic rotation angle sensor allows you to use magnets of various materials. If the required magnetic flux density is satisfied, the specifications are guaranteed regardless of the magnet material and size. You can select magnets flexibly depending on the cost and size of the motor system.

For details, refer to the Magnet Selection Guideline.

For more details, contact us with the inquiry form.