Bluetooth® Low Energy tag

Energy Harvesting

Bluetooth® Low Energy tag to identify locations of persons and properties

In recent years, the use of Bluetooth® Low Energy (BLE) tag has increased to prevent pallet losses in logistics warehouses and to detect locations of employees in free-address offices. A Bluetooth® Low Energy tag is required to be lightweight and compact as it is attached to a person or an object. Another important feature is that it does not require battery replacement in offering subscription-based IoT services.

This article introduces an ultra-compact, battery-free Bluetooth® Low Energy tagging system that utilizes Asahi Kasei Microdevices Corporation (AKM) energy harvesting IC.

* Bluetooth® is a registered trademark of Bluetooth SIG, Inc.

Lightweight and compact

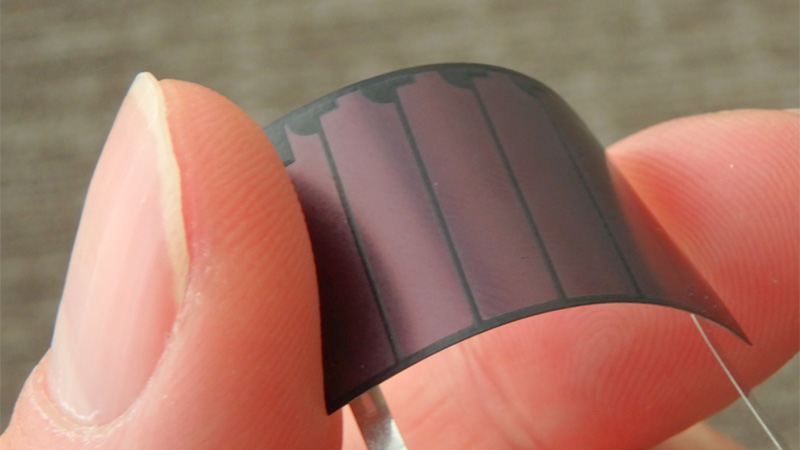

By combining AKM's energy harvesting IC with small solar cells, Bluetooth® Low Energy tags can be made lighter and smaller. For this reason, it can be attached on the employee ID neck strap without any discomfort to the employee.

High flexibility in mounting location

For employee ID, it can be attached not only on the neck strap but also near the reel. In addition, since energy can be stably collected even in low-light environments such as logistics warehouses, periodic battery replacement is not required even after attaching to a large number of pallets in the warehouse.

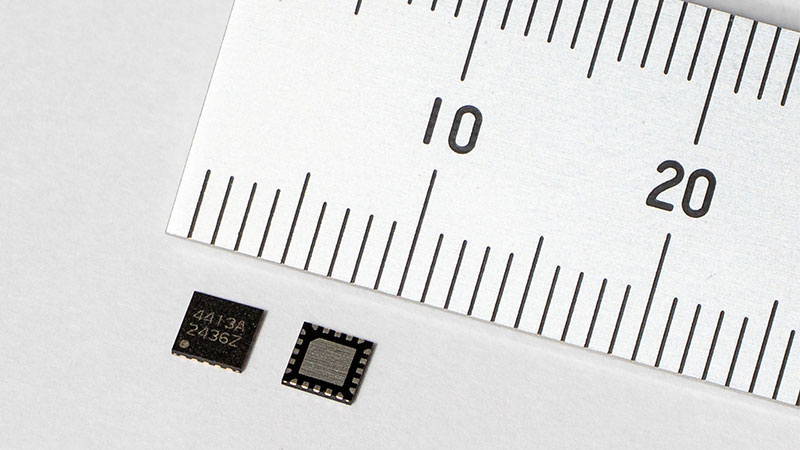

Low power consumption comparator is the key to the miniaturization

Since small PV cells have low power output current, the collected energy must not be self-consumed by the power supply circuit, so it is essential to configure the circuit with an IC that utilizes a low current. AKM's Energy Harvesting IC can detect the voltage-rise of a storage device by using ultra-low-consumption comparators with an operating current of 26nA. When the IC detects that the voltage has risen to the threshold, it starts supplying power to the MCU and the radio IC and makes a radio transmission.

System blocks for Bluetooth® Low Energy tag

When connecting a power generation device that does not require boosting, such as a solar cell with a large cell count, which is 6, the voltage of capacitors and rechargeable batteries can be monitored as a low-power-consumption comparator with an operating current of 26nA without using a booster circuit. Reduction of the number of components is also possible because an inductor for boosting voltage is no longer required.

What makes AKM different ?

See "Why energy harvesting IC by AKM are Selected".