High accuracy even in compact

CO2 sensors have been widely adopted over various fields in recent years. Senseair's CO2 sensors have been popular customers' choices since the early days of the marketplace. The benefits of Senseair products are discussed here by referring to solving problems in buildings.

CO2 Sensors

Senseair's CO2 sensors help make efficient HVAC systems for customers, thanks to their features of high accuracy, compactness, and a stable system for more than 15 years, regardless of installation conditions.

Challenges of air-conditioning management systems include fine control for human comfort, sensor installation according to the shape and usage of each building, and mid-term and long-term stability and low maintenance costs.

Senseair's CO2 sensor features high-accuracy, a compact design that offers greater flexibility in your installation location, and its unique self-compensating feature allows you to use it maintenance-free for a long period of time.

Temperature characteristics of CO2 sensors (competitor comparison)

This white paper compares the variation of CO2 concentration detected against temperature for different CO2 sensors. Read this white paper to find out why you should choose Senseair.

Energy cost reduction through optimization of air conditioning and ventilation

HVAC (heating, ventilation, and air-conditioning) systems for buildings are designed to prevent the CO2 concentration from exceeding its threshold level.

In recent years, air quality monitors are being used to optimize the air-conditioning and ventilation of each room by monitoring the CO2 level in order to reduce the power consumption. The American Society of Heating, Refrigerating and Air-Conditioning Engineers reports that energy costs can be cut by 30% by optimizing air-conditioning and ventilation by using air quality monitors. [1]

[Notes]

[1] https://www.meghvac.com/wp-content/uploads/2016/05/2016Jan_030-037_Lin.pdf

Challenges for optimizing HVAC systems

What are the challenges in optimizing HVAC systems? Based on the knowledge obtained over the past 25 years, we believe that the following will be the three major issues.

Highly accurate and less irregular data collection

Extreme care must be taken with regard to HVAC control as human senses are very sensitive. When the results measured by the air quality monitor are used for control purposes, it is desirable that CO2 concentration measurements be of high accuracy. In addition, considering the seasonal changes and the movements of people, it is preferable to minimize fluctuations in the characteristics due to environmental conditions.

For comparison, LEED (Leadership in Energy & Environmental Design), a Green Building Certification System, states that CO2 sensors with a measuring accuracy of 75ppm or less should be used.

Sensor installation in a variety of locations

Various factors such as the shape of the building and the movements of people vary within each building. Naturally, the location of the sensors must also be examined within each building. The smaller the shape and size of the air quality monitor, the greater the freedom of the placement location.

Stable operation over the medium to long term

Buildings that will last decades require a stable system over the medium to long term. It is also necessary to consider the maintenance costs, such as calibration of the inspection system.

Air quality monitors that are required for air conditioning systems for buildings

Senseair provides CO2 sensors that solve the above three issues for optimization of HVAC systems.

Highly accurate data acquisition is possible regardless of the installation environment

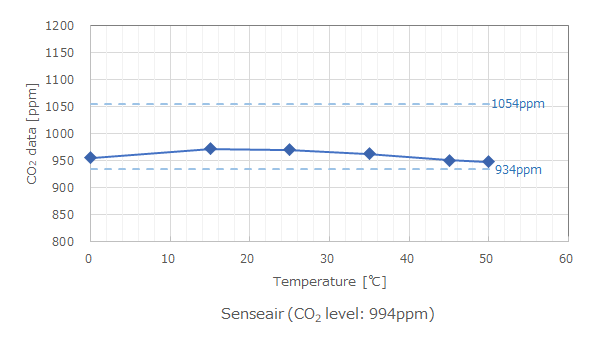

Senseair's CO2 sensor achieves high measurement accuracy of ± (30ppm + 3% of reading range) with minimal detected concentration fluctuations with respect to temperature. HVAC systems can be developed independently of the environmental temperatures of the installation sites. This makes the system design simpler.

Senseair calibrates all of its products at several temperatures before shipment. For this reason, the errors of the detected concentration are small over a wide operating temperature range.

For comparison, many other companies' products are calibrated at only one temperature, so accurate measurements can only be obtained at the calibrated temperature.

Temperature characteristics of Senseair's CO2 sensors

Temperature characteristics of Senseair's CO2 sensors

High installation flexibility due to its compact size

Since the accuracy of NDIR type CO2 sensors generally depends on the optical path length (the distance from the infrared light source to the infrared sensor), high accuracy CO2 sensors had to be larger in size. However, Senseair has designed the sensors to realize a long optical path length even in a compact space by devising an optical design, achieving both compactness and high accuracy.

The high accuracy and compactness of CO2 sensors provides flexibility in the location of the sensors in the building, allowing system integrators to consider a more flexible ventilation system.

Stable system for more than 15 years

Senseair's CO2 sensors are maintenance-free for more than 15 years of use. This is achieved by the ABC (Automatic Baseline Correction) algorithm, which is a self-correcting function built into all sensors of Senseair. Common CO2 sensors require regular calibration because the accuracy of the sensors is reduced due to vibrations during handling, stresses on the circuit board, reduced light emission from the light source, and contaminated light paths.

Senseair's CO2 sensors, on the other hand, are programmed to register the lowest CO2 concentration values over a period of time (default: 8 days) and to adjust the zero point if a difference is detected from the outside air CO2 concentration of 400ppm.

Temperature characteristics of CO2 sensors (competitor comparison)

This white paper compares the variation of CO2 concentration detected against temperature for different CO2 sensors. Read this white paper to find out why you should choose Senseair.

Recommend

About Senseair

Senseair, which became a member of the Asahi Kasei Microdevices (AKM) Group in 2018, is a provider of gas sensors using NDIR: Non-Dispersive InfraRed technology. Our goal is to constantly develop and mass-produce new gas sensor technologies.