Rotation Angle Sensors

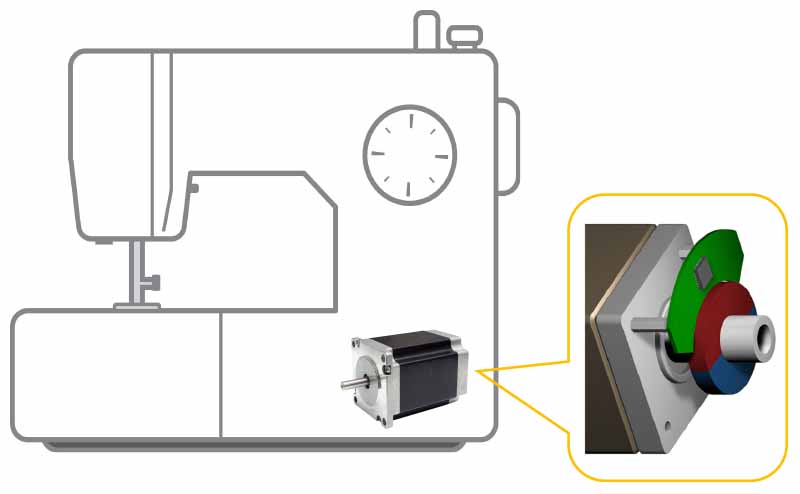

Encoder in an industrial sewing machine

Encoder in an industrial sewing machine

How to use rotation angle sensors

- For industrial sewing machine application -

Application Proposal #02

Young K

Young K

~ Struggles of a salesperson for angle sensors ~

Young K, who works in Asahi Kasei Microdevices and is in charge of rotation angle sensors (encoder ICs).

This is a story of how he grows as a salesperson while reporting to his boss, Manager F.

In the office

Manager F

I received a request for information materials from company B, an industrial sewing machine manufacturer. Can you check the details and reply to them?

Young K

Sewing machine... does it need an encoder?

Manager F

Oh, haven't you worked with an industrial sewing machine customer before?

Young K

No.

Manager F

Well, it's your first time. Industrial sewing machines and embroidery machines have many motors in them, so they need some encoders. For moving a needle, winding up a thread, and pressing down cloths. And magnetic encoders are preferable to use. Can you guess why?

Young K

Well, that's because they are a non-contact type.

Manager F

As you can image that it's easy to get lint and dust inside a sewing machine.

Young K

Oh, the magnetic encoder works well even in poor environments!

Manager F

Yes. The inside of the sewing machine has oil running through it, so many customers are concerned about that kind of dirt as well.

Young K

So the poorer the environment is, the more advantageous the magnetic system can be!

A few days later

Young K

I talk to company B's designer on the phone after sending the materials, and he requested a sample.

Manager F

Did you hear his use application?

Young K

The motor that carries the cloth.

Manager F

What made him interested in our products?

Young K

One is cost reduction. Company B is using an optical encoder now, so they need to seal it for dirt prevention. They wanted to omit that.

Manager F

Well, we've heard that a lot.

Young K

The second reason is miniaturization.

In the current model, the encoder is placed in a tight space. But the next model has even more limited installation space, he said.

Manager F

You learned that through our robot customer the other day, so you understand, don't you?

Young K

Yes, I emphasized the miniaturization that can be achieved with our product.

Manager F

Do you have any concerns?

Young K

It's going to require calibration to achieve an angular accuracy of 0.1 or 0.2 degrees. He hopes it won't be an additional work.

Manager F

Even though it's called a calibration, the user doesn't have to do that every time they run a sewing machine. It's a one-time calibration when company B assembles it at the factory.

I think it's no problem If you explain it properly.

* Please note the volume of background music.

After the meeting with the customer

Young K

I visited company B. They'll start evaluating the AK7455 next month.

Manager F

You pass through the first gate. Are there any competitors?

Young K

They firstly considered magnetic encoders as our competitor too. But the AK7455 was their first choice because they found that an angular error of 0.1 degrees can be achieved with a simple calibration.

They also said that the ability to set the ABZ output resolution freely was a good point.

Manager F

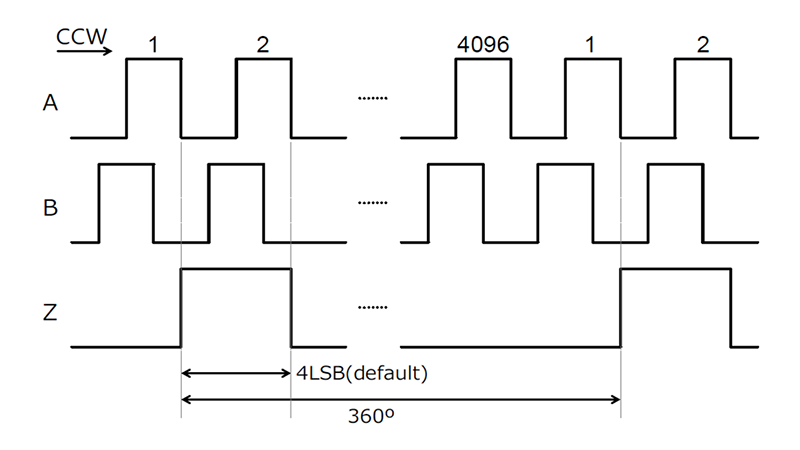

Do you understand the benefits of adjusting the ABZ resolution? This means that the number of pulses per revolution can be set freely.

In case of replacing an existing encoder, they must choose an encoder with the same number of pulses, otherwise they'll have to change the software, which is a big hassle. In contrast, no matter what pulse count, the AK7455 can cover it with one product because the ABZ phase resolution of the AK7455 can be set in the range of 1 to 4096 ppr.

ABZ Incremental Output

ABZ Incremental Output

Young K

I understand now...

Manager F

We hope they will consider using the AK7455 for purposes other than cloth feeding as well.

Young K

The designer said he was a little dissatisfied with the encoder that presses the cloth down, so I'll go and ask him for more information.

Manager F

In addition to industrial sewing machines, yarn-related equipment such as knitting machines and spinning machines may have similar problems, so you should promote our encoder individually.

Young K

Yes, I will keep in touch with our customers like a long sewing thread.

A message from young K to you

Young K

Young K

Young K

If you are considering an encoder solution, we can help you in various ways such as demo, sample, or quote.

Please feel free to contact us.