What makes AKM different ?

Rotation Angle Sensors

Currently, optical encoders are the most commonly used in the world. While there have advantages such as high accuracy and high resolution, they are is also susceptible to contamination such as from oils and dust, and a complicated structure is required to detect the absolute angle. Therefore, magnetic encoders are attracting attention as a solution to these problems. AKM's magnetic rotation angle sensors have contributed to the realization of magnetic encoders that can solve the problems of conventional optical encoders. AKM's rotation angle sensors have a variety of features that can compensate for the disadvantages of conventional magnetic angle sensors. Here are the three points for which AKM's rotation angle sensors are chosen.

Achieves ±0.1 degree high accuracy with a simple configuration

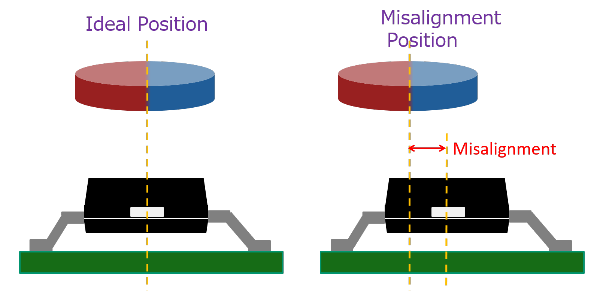

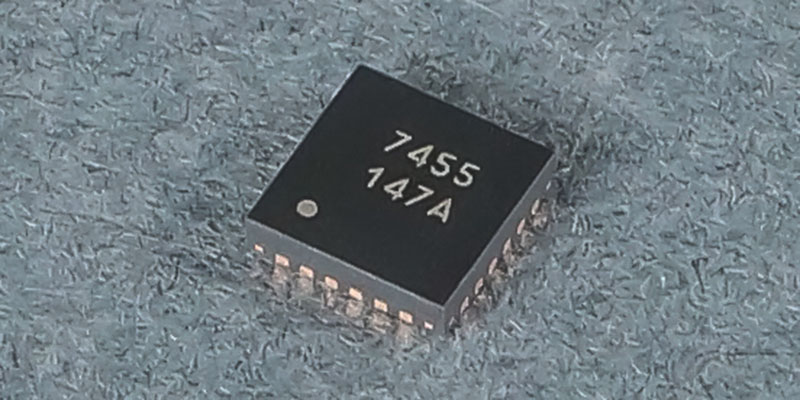

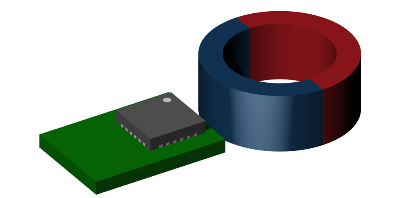

While applying a simple configuration that can be used with 2-pole magnets, AK7455 can achieve absolute angle output at a high accuracy with its unique angle error calibration function. It is ideal for industrial robots and actuators that require a high accuracy of ±0.1 degree. In addition, since the angle can be corrected by a simple procedure including errors due to assembly tolerances, fine mounting position adjustment is not required.

Off-Axis

While conventional magnetic angle sensors can only be positioned at the Shaft-End, AK7455 is capable of axis penetration positioning (Off-Axis), achieving high accuracy. This allows both ends of the motor shaft to be used and the shaft can be hollowed to allow cables, air, water, etc. to pass through the shaft.

Resistance to Ageing

AK7455 uses a unique transverse magnetic field sensing system, which makes it less susceptible to displacement due to motor loads or to aging displacement due to long-term operation, compared to the AMR system with the same transverse magnetic field sensing.