Why Senseair's flammable refrigerant sensor is chosen

Launch of highly safe gas sensor in anticipation of regulatory trends

Flammable Gas Sensors

R32 refrigerant gases that are used in many air conditioners are slightly flammable. However, there is a risk of being burnt if they are used in large air conditioners as they are used in large quantities. Additionally, as the use of highly flammable gas R290 (Propane) becomes more widespread, it is important to note that even a small leak can lead to serious incidents such as fires or major explosions due to its high flammability. For this reason, an increasing number of products are equipped with sensors that detect refrigerant gas leaks. However, sensors so far had various challenges, such as the risk of igniting leaking gases.

In order to solve these problems, we introduce here flammable refrigerant (R32, R290, R454 A/B/C) sensors, which has been newly developed by Senseair, an AKM's group company.

Risk of refrigerant leaks from air conditioners and trends of regulations

While there are several options for refrigerants used in air conditioners, in response to the increasing awareness towards global environmental issues, manufacturers have begun to adopt those with low global warming potential. In general, however, refrigerants with lower global warming potential tend to have higher flammability, increasing the risk of fire due to refrigerant leaks.

Considering such refrigerant properties as these, there is an increasing trend for equipping a gas sensor in large air conditioners, in particular, to detect refrigerant leaks. While the regulations governing gas sensors vary depending on the countries and regions, there are moves in the United States to tighten the regulations governing sensor performance. Following the U.S., the trends in other regions are also being watched closely.

In light of these trends, Senseair has developed a micro-flammable refrigerant (R32) sensor, mixed refrigerant (R454A/B/C) sensor, and highly flammable refrigerant (R290) senor. Sensors that can detect refrigerant gases have been developed using the technology similar to our CO2 sensor, which has already proven records.

The technology is called an NDIR method. Semiconductor-based sensors have been the most popular type of flammable refrigerant sensors for air conditioners. However, there are many challenges with the semiconductor type, and many air conditioner manufacturers have been searching for solutions. One possible solution is Senseair's NDIR Flammable Refrigerant Sensors.

Features of the NDIR method and semiconductor-based method

While the NDIR method measures the absorption of infrared rays by the gas, the semiconductor-based method detects changes in resistance values that vary depending on the oxidation-reduction reaction between the gas and the semiconductor. They are quite different and each has its own unique characteristics.

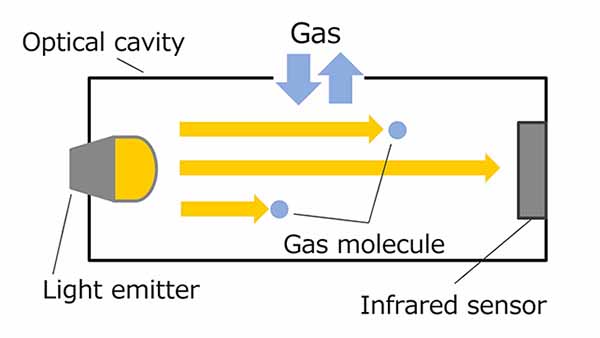

In the NDIR method, a constant light is irradiated from a light source in the sensor and is delivered to the light-receiving element. Flammable gases taken into the sensor receive the light from the light source. Because flammable gases absorb light of specific wavelengths as their characteristics, the light-receiving element detects the light attenuated by absorption against the light illuminated from the light source. The concentration of flammable gases can be detected from the degree of attenuation of this light. The NDIR method, which has a high gas selectivity, does not react to any gases other than flammable gases, ensuring high detection accuracy. Its features are described later.

NDIR method

NDIR method

On the other hand, the semiconductor-based method uses a heater to heat materials that react to gases to increase the sensitivity and detects chemical reactions with flammable gases. The issue in terms of accuracy is raised for this method as the reactions vary depending on the humidity. This method has a low gas selectivity in terms of detecting target gases only. Due to these differences in properties, there is an increasing trend in focusing on the NDIR method among the air conditioner manufacturers.

High safety, high reliability and long life, eliminating ignition risk

Senseair's flammable coolant sensors have acquired unique strengths by using LED as the light source, while employing the NDIR method. The key words are safety, high reliability, long life, low power consumption, compact size, and high accuracy (Fig.).

Firstly, about safety.

LED hardly generates any heat and the sensor runs at a temperature nearly equal to the ambient temperature. Therefore, even if a flammable gas leaks, it will not become an ignition source. We believe that the high level of safety is the most important advantage of the product.

Some sensors of the same NDIR type use a lamp as the light source. When the light is emitted, the heat generated from the filament part of the lamp rises above 1500°C, presenting a risk of ignition. Some sensors use a MEMS heater and this also generates heat and emits light at a temperature around 700°C. Consequently, considering the ignition temperature of refrigerant gas, a similar risk cannot be eliminated.

High safety, high reliability and long life, eliminating ignition risk

High safety, high reliability and long life, eliminating ignition risk

Secondly, high reliability and long life.

According to our survey, the chance of failure due to lamp burn-out, etc., was 1000ppm in about 10 years. When a lamp burns out, maintenance such as parts replacement becomes necessary, increasing the life-cycle cost.

On the other hand, the long life of LED is well recognized. The failure rate of LED used in Senseair's flammable refrigererant sensors is 1ppm or less over 15 years. In addition, it has a proprietary compensation algorithm called ABC (Automatic Baseline Correction*), which enables it to run maintenance-free for a long time. In the sense of initial cost, our products are more expensive than NDIR sensors using a semiconductor method or other light sources, but we believe that they have more advantages in terms of long-term operation.

*What is ABC?

ABC (Automatic Baseline Correction): A method of correcting the output value of a sensor based on data measured within a certain period of time.

*Please also refer to this section for the features of the NDIR method.

Strength based on the ultra-low power consumption and high accuracy

Thirdly, ultra-low power consumption.

This is the property of LED itself. In the case of a lamp, when a current is applied, the filament is first heated before it emits light, taking several hundred milliseconds before the lamp emits light. In contrast, LED that is used in Senseair's flammable refrigerant sensors emits light within hundreds of microseconds after the current is applied. Since there is no need for heating, the power consumption can be greatly reduced.

Fourthly, features of compact in size and high accuracy, which are achieved based on Senseair's unique technique.

In the NDIR method, the greater the distance between the light source and the light-receiving element, the more frequently the light hits the gas molecules.

Along with this, the detection accuracy also increases, but on the other hand, the size of the sensor itself increases. Senseair has established a unique optical path designing technique that reflects light many times inside the sensor, thereby increasing the distance between the light source and the light receiving element despite its compact size. This has resulted in a compact and high accuracy flammable refrigerant sensors.

While the regulatory demands are increasingly stringent for sensors, Senseair is able to provide sensors with performance that can comply with standards for accuracy and responsiveness.

There is a growing need for gas sensors that are designed with an awareness of sustainability.

Senseair's flammable refrigerant (R32, R290, R454 A/B/C) sensors with four strengths presents solutions to the traditional challenges. An increasing number of air conditioner manufacturers are paying attention to this advanced technology. Quick detection of leaks of refrigerant gases is required for air conditioners. In the future, refrigerant gases with higher combustion risk may be used to reduce the global warming potential (GWP).

While the future movement of regulations in each country and region in this field is not necessarily clear, regulations related to sustainability and safety will become more stringent. We believe that the need for more reliable and safe sensors will grow more and more.

About Senseair

Senseair, which became a member of the Asahi Kasei Microdevices (AKM) Group in 2018, is a provider of gas sensors using NDIR: Non-Dispersive InfraRed technology. Our goal is to constantly develop and mass-produce new gas sensor technologies.