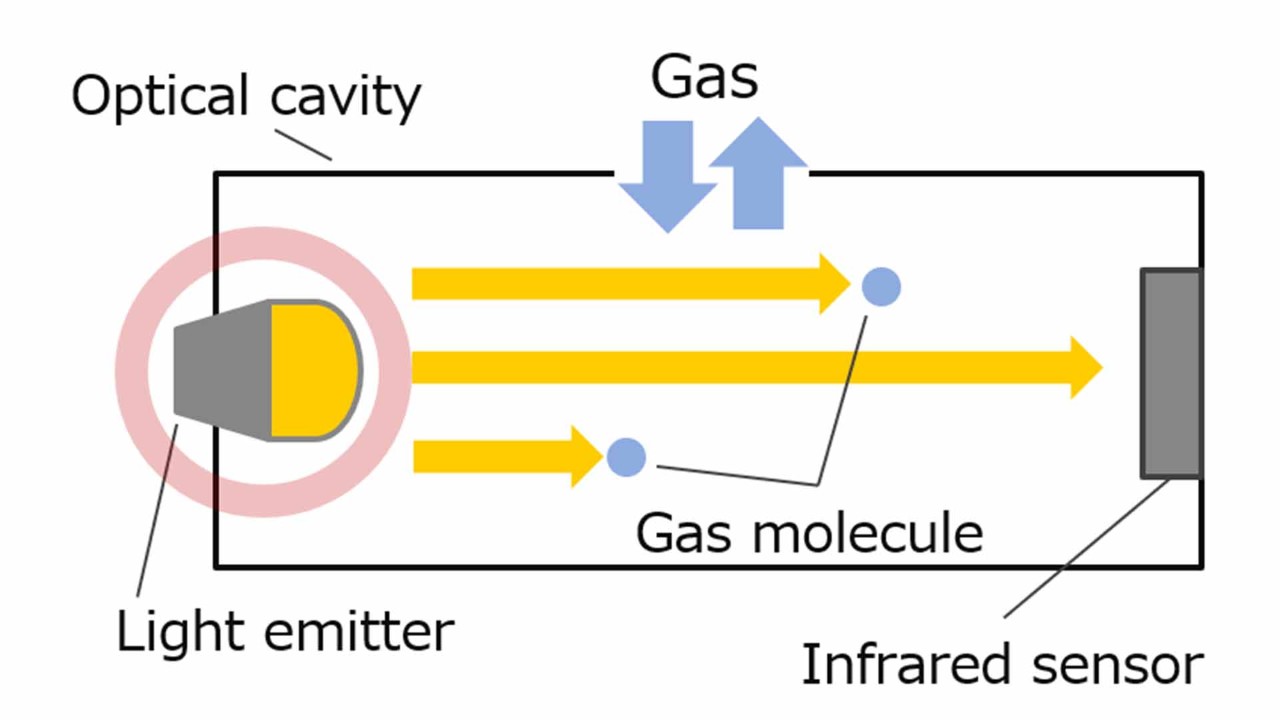

What is NDIR?

CO2 Sensors

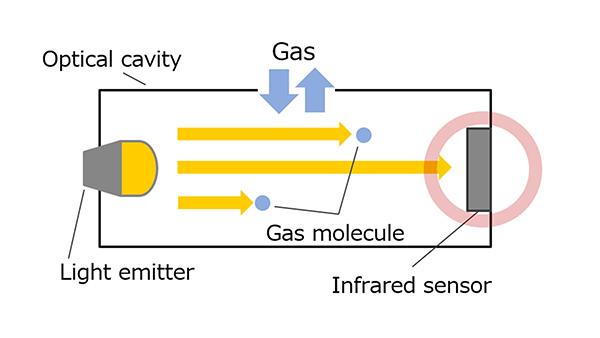

A NDIR type gas sensor calculates the gas concentration by using the property that gas molecules (e.g., CO2) absorb infrared rays. Therefore, a NDIR type gas sensor is equipped with an infrared light emitter that emits infrared light and an infrared sensor that detects infrared light, and the performance of NDIR type gas sensor varies depending on the type of the light emitter and the infrared sensor that is installed. This section explains each component.

Component 1 : Infrared Light emitter

Light emitters can be broadly classified into two types: optical type and thermal type. The optical type directly converts current into light by using the recombination of electrons and holes in a semiconductor. The thermal type emits light by supplying current to the heat element and consequently heating the object. Each type is explained together with the specific features of the product.

The chart below compares the three light emitters (the ✓ has advantages and the ✗ has disadvantages).

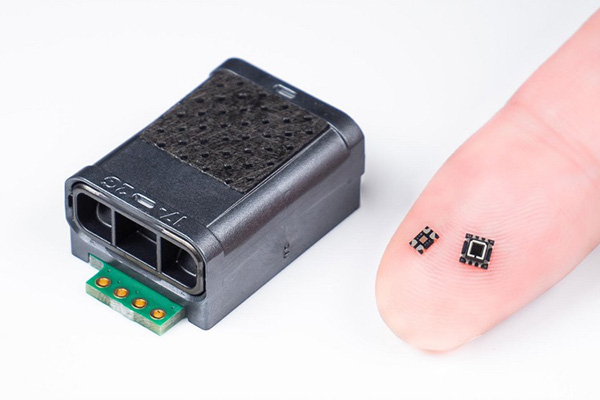

Figure 1. Light emitter of NDIR type CO2 sensor

Figure 1. Light emitter of NDIR type CO2 sensor

Table 1. Comparison by different infrared light emitters

| Light emitter | LED | Lamp | MEMS heater |

|---|---|---|---|

| Type | Optical type | Thermal type | Thermal type |

| Response time | ✓ | × | × |

| Current consumption | ✓ | × | × |

| Life time | ✓ | × | × |

| Surface mounting | ✓ | × | × |

1-1: LED (Optical type)

When a forward voltage is applied to an LED (light-emitting diode), electrons and holes move, causing recombination. When this recombination occurs, the light of the wavelength specific to the substance is emitted. LEDs in the visible region of the human eye, such as white LEDs and blue LEDs, are used throughout everyday life. However, because many gas molecules have absorption wavelengths in the infrared region rather than in the visible region, LEDs that emit infrared light suitable for NDIR type gas sensors are required. For this reason, Asahi Kasei Microdevices (AKM) is developing LEDs with emission wavelengths in the infrared region where gas molecules are absorbed.

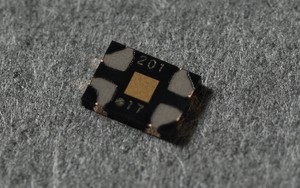

Figure 2. LED (Infrared Light emitter of NDIR type CO2 sensor)

Figure 2. LED (Infrared Light emitter of NDIR type CO2 sensor)

LEDs are superior as a light emitter for NDIR type gas sensors. Compared to thermal type light emitters, LEDs respond much faster and reduce light emitting time without limit, thereby reducing the gas sensor power consumption. Actually, gas sensors that can be driven for four years by batteries are commercially made available by using infrared LEDs and infrared sensors of AKM. (Refer to application / Customer story of SAF Tehnika.) Battery-powered devices enable customers to easily and accurately measure the CO2 concentration anywhere. In addition, because LEDs convert current directly into light, the LEDs themselves do not become hot and do not become an ignition source, making them the suitable solution for use as a gas sensor light emitter, such as a flammable refrigerant gas.

The configurations of the sensors for such combustible gases are strictly defined by IEC standards, and the safety is remarkably improved by using LEDs with extremely low heat generation. Regarding the LED package, AKM uses a resin package for its surface mounting adaptability and vibration-resistant feature.

1-2: Lamp (Thermal type)

When current is supplied to a filament in a lamp, Joule's heat is generated, thereby heating the filament and emitting light due to a high temperature. This is the mechanism for illuminating a lamp. Tungsten, which is commonly used for a filament, can reach temperatures as high as 2000°C. to 3000°C. Since filaments become extremely hot, the inside of the bulb is encapsulated with a rare gas or a halogen gas to prevent the filaments themselves from being oxidized or evaporated.

The lamp is a very common old-fashioned infrared light emitter and can also be useful as a light emitter for gas sensors. Gases have an inherent absorption of infrared rays depending on the type of gas. Since a lamp can emit light at a variety of wavelengths from the visible region to the infrared region at once, a single lamp can accommodate a variety of gas types.

Therefore, a lamp can be used as a general-purpose light emitter. Since a thermal infrared light emitter requires time for the temperature to rise and to emit light, and accordingly, the time for applying a voltage also increases, resulting in greater power consumption. In addition, due to the vulnerability of the filament towards vibrations, care must be taken in the surrounding environment of a gas sensor installed when a lamp is used as an infrared light emitter of a gas sensor.

Figure 3. Lamp (Infrared Light emitter of NDIR type CO2 sensor)

Figure 3. Lamp (Infrared Light emitter of NDIR type CO2 sensor)

1-3: MEMS heater (Thermal type)

The principle of light emission is the same as that for lamps, which uses heat generation as the source. A MEMS heater generates heat and emits light when electric current is supplied to a thin film of a resistance heating element that is processed by a semiconductor process. Due to the importance of heating the filament to a high temperature, a MEMS heater light emitter is designed giving consideration to the heat conduction of surrounding materials such as application of an extremely small filament and a narrow heat conduction path to prevent the heat from escaping (such as folding back and spiral pattern).

Among thermal-type light emitters, a MEMS heater is designed to have a specifically small heat capacity to facilitate heat generation so that the response speed is faster than a lamp and slower than LED. Also, since MEMS heat does not become as hot as a lamp, the emission wavelength band is narrower than that of a lamp, but wider than that of an LED. If it matches the absorption wavelength of a gas, a MEMS heater can be used as a light emitter for a gas sensor with a faster response than a lamp.

As a MEMS heater has a microstructure, it has a disadvantage of being vulnerable to vibrations similar to a lamp. In addition, since the hot part is exposed, a MEMS heater is unsuitable for measuring flammable gases as an infrared light emitter.

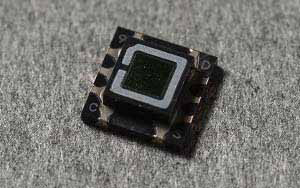

Figure 4. MEMS heater (Infrared Light emitter of NDIR type CO2 sensor)

Figure 4. MEMS heater (Infrared Light emitter of NDIR type CO2 sensor)

Component 2: Infrared Sensor

Infrared sensors can also be broadly classified into two types: optical type and thermal type. The optical type uses the photovoltaic power of a semiconductor to directly convert light into current. The thermal type uses a method that detects a voltage or polarization caused by a temperature difference when an object gets warm. Each type is explained together with the specific features of the product.

The chart below compares the three infrared sensors (the ✓ has advantages and the ✗ has disadvantages).

Figure 5. Infrared sensor of NDIR type CO2 sensor

Figure 5. Infrared sensor of NDIR type CO2 sensor

Table 2. Feature of Infrared Sensor

| Infrared sensor | Photodiode | Thermopile | Pyroelectric sensor |

|---|---|---|---|

| Type | Optical type | Thermal type | Thermal type |

| Response time | ✓ | × | × |

| Life time | ✓ | × | × |

| Surface mounting | ✓ | × | × |

2-1: Photodiode (Optical type)

Light (infrared ray) is absorbed in the depletion layer formed by joining a P-type semiconductor and an N-type semiconductor, generating photovoltaic power. Photodiodes make use of this principle. Generally, it is believed to be difficult to separate the current caused by photovoltaic power from the noise current caused by heat without cooling the photodiode that has the sensitivity in the mid-infrared region.

AKM has mass produced mid-infrared photodiodes, which can be used without cooling, using the semiconductor thin-film technology for InSb. In addition, the wavelength of the light that is absorbed is inherent to the material of photodiodes, and it is important to have sensitivity in the infrared region, which is the absorption wavelength band of gas molecules in order to use photodiodes as infrared sensors for gas sensors. For this reason, AKM offers a line-up of photodiodes with optimized sensitivities in the 3.3um band for combustible gases and refrigerant gases, and sensitivities in the 4.3um band for CO2 to enable customers to select and use NDIR type gas sensors according to the applied gases.

Figure 6. Photodiode (Infrared sensor of NDIR type CO2 sensor)

Figure 6. Photodiode (Infrared sensor of NDIR type CO2 sensor)

Since the photodiode is a photo type detector, its response speed is overwhelmingly faster (typ. 2 μs) than that of a thermal type detector. Therefore, by incorporating this photodiode into a NDIR type gas sensor and combining with LED of an infrared light emitter, the power consumption can be reduced (Sensor Core Sunrise). In fact, gas sensors that can be driven for more than 1 year by batteries are commercially available by using LEDs and photodiodes of AKM (Customer story). Regarding the photodiode package, AKM uses a resin package for its surface mounting adaptability and vibration-resistant feature.

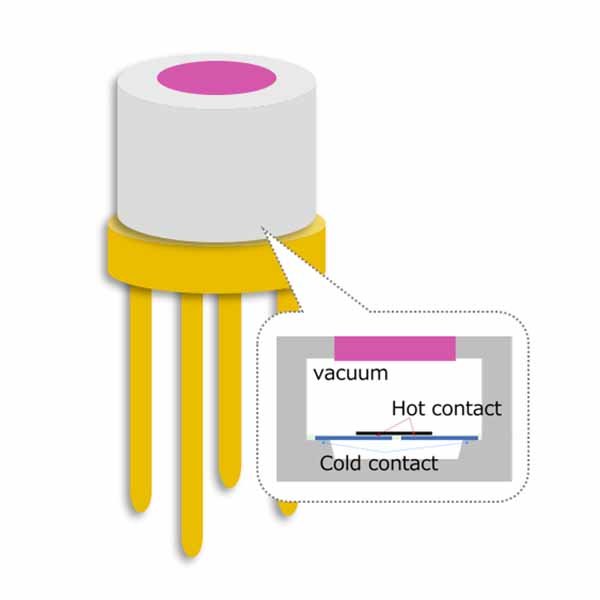

2-2: Thermopile (Thermal type)

A thermopile is an infrared sensor that utilizes the Seebeck effect, in which the temperature difference of an object is converted to a voltage. An object that generates a temperature difference is called a thermopile. The warmer side is called a warm junction, and the cooler side is called a cold junction. To facilitate a temperature difference, a thermopile is structured so that heat is easily collected by an infrared absorbing film on the warm junction and the cold junction is arranged so that heat escapes easily. A thermopile is connected in series to increase the electromotive force.

A can package such as TO-5 is mostly applied for the packaging form. The package is designed to prevent heat from escaping as much as possible by reducing the thermal conductivity by vacuuming the can and to avoid the impact of environmental humidity by sealing the can with nitrogen gas.

Since a thermopile is sensitive to infrared rays over a wide range, it can be used as an infrared sensor to be installed in NDIR by using an optical filter ideal for the thermopile and target gas. Various gases can also be detected by changing the optical filter. However, the response speed of a thermopile is not fast since it is a thermal infrared sensor, requiring time to reach a temperature difference (>200msec).

Therefore, the driving time of the infrared light emitter becomes longer and the power consumption inevitably increases. Also, this thermopile type sensor is unsuitable for environments where damage to the package may occur due to vibration, such as in automobiles because of its vacuum or the sealing gas inside of the package.

Figure 7. Thermopile (Infrared sensor of NDIR type CO2 sensor)

Figure 7. Thermopile (Infrared sensor of NDIR type CO2 sensor)

2-3: Pyroelectric Sensor (Thermal type)

In a pyroelectric sensor, ferroelectrics receive infrared rays and become warm. As a result, internal polarization changes, generating an electric charge. This phenomenon is called the pyroelectric effect, which is used for a pyroelectric sensor.

Ferroelectrics include PZT (lead zirconate titanate), lead titanate, and barium titanate. Many pyroelectric sensors apply a vacuum can package structure due to their humidity dependency.

As with thermopiles, pyroelectric sensors are also sensitive to an infrared region over a wide area. Therefore, they can be used as NDIR infrared sensors by attaching an ideal optical filter for the gas. Pyroelectric sensors, which are also thermal infrared sensors, take time to warm the ferroelectrics, slowing down the response speed (>200msec).

Therefore, as with thermopile, the driving time of the infrared light emitter increases, inevitably increasing the power consumption. Also, this pyroelectric type sensor is unsuitable for environments where damage to the package may occur due to vibration, such as in automobiles because of its vacuum inside of the package.

Figure 8. Pyroelectric Sensor (Infrared sensor of NDIR type CO2 sensor)

Figure 8. Pyroelectric Sensor (Infrared sensor of NDIR type CO2 sensor)

CO2 Sensors

Flammable Gas Sensors

About Senseair

Senseair, which became a member of the Asahi Kasei Microdevices (AKM) Group in 2018, is a provider of gas sensors using NDIR: Non-Dispersive InfraRed technology. Our goal is to constantly develop and mass-produce new gas sensor technologies.