Rotation Angle Sensors

How to use rotation angle sensors

- For robot application -

Application Proposal #01

Young K

Young K

~ Struggles of a salesperson for angle sensors ~

Young K, who works in Asahi Kasei Microdevices and is in charge of rotation angle sensors (encoder ICs).

This is a story of how he grows as a salesperson while reporting to his boss, Manager F.

After the first meeting with the customer

Young K

I've just visited Company A, which contacted us from the Web.

Manager F

You talked about the company looking for an encoder in the joints of a service robot, didn't you? Why were they interested in our angle sensors?

Young K

At first, they considered using an optical encoder, which has been used in large robots. But it was too big to fit. They said there wasn't much space available because the gear reducer and various other parts were incorporated in the joints.

Manager F

I see.

Young K

Resolver was next on the list, but they gave up on it because a complicated design was very hard for them. I forgot to ask them, what is so troublesome about it?

Manager F

The resolver is shock-resistant, and it has been used in car application for a long time. But a lot of designers don't like analog output. And the size isn't that small. So, do our products meet their specifications?

Young K

14-bit resolution and an angular error of less than +/-0.1 degrees are required. So I think the AK7455 is generally fine. Also, they were interested in the words "small and thin".

Manager F

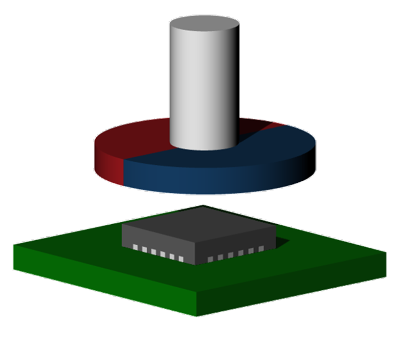

Okay, the sensor position is Shaft-End or Off-Axis configuration?

Young K

Off something..., what was it again?

Manager F

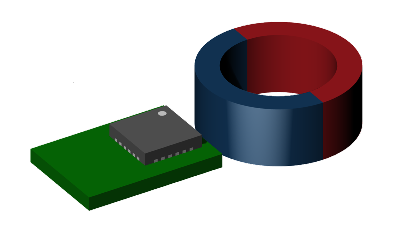

What? You met the customer without knowing that! A shaft-end configuration is where the magnet center and sensor center are aligned on the axis of rotation. An Off-Axis is a configuration where the sensor center is not located on the rotational axis. This configuration enables the end of shaft to be used freely, so that it is available for dual shaft motors and hollow shaft motors...maybe you cannot understand well what I said, so I'm drawing.

Shaft-End Configuration

Shaft-End Configuration

Off-Axis Configuration

Off-Axis Configuration

Young K

Okay, I see. Then it is Off-Axis this time.

Manager F

So, can you explain the benefits of Off-Axis configuration?

Young K

Well... Is it because Off-Axis gives us a lot of flexibility of the sensor placement?

Manager F

Yes, that's right. But can't you explain the specific benefits? To answer first, for example, the encoder itself can be made thin. Also, with a hollow shaft, wires can be run through it. The angle of double shaft motors can be measured as well.

Young K

I see, our customers can use it in various patterns. This customer said they just wanted to make it thinner anyway.

After the second meeting with the customer

Young K

I demonstrated the angle measurement in front of the customer and it was a great success.

*The background music is playing.

Manager F

Well, do you think they can use it well?

Young K

I've received a request from customers to run it themselves, so I provided them samples to evaluate.

Manager F

Are there any other points that we should be keeping in mind?

Young K

The customer are not familiar with magnetic sensors, so they felt uneasy about using our sensor well.

Manager F

You'll just have to support them properly. Once the design is in place, you can give them some information about magnet selection and detailed placement by using magnetic simulations. Be more confidence, otherwise your anxiety is contagious to your customer.

Young K

I understand. I'll keep checking on the situation.

A few months later

Young K

Thanks to you, the customer have progressed to the prototype manufacturing step.

Manager F

Oh, was the design fixed before I know it?

Young K

Our magnetic simulation allowed them to fine-tune the sensor placement. And it fit perfectly into the empty space inside the joint!

Manager F

This theme is a good case study that the AK7455 layout flexibility realized a thinner design. By the way, didn't you have a problem with the price?

Young K

I was able to offer the AK7455 solution at lower cost than optical encoders.

Manager F

There are all sorts of optical system, but I suppose magnetic encoders are cheaper than optical encoders in many cases, comparing same specs.

Young K

I'm much more confident. I think I'm going to sell our products a lot more.

Manager F

It's still early... well, I'm sure we will take more robotics-related theme in the future. I hope you gain a little bit of experience. Come to think of it, we just received an inquiry from company B about a hollow encoder for robot hand. Do you want to take charge?

A message from young K to you

Young K

Young K

Young K

If you are considering an encoder solution, we can help you in various ways such as demo, sample, or quote.

Please feel free to contact us.