Simple Calibration for angle accuracy of 0.1°

Rotation Angle Sensors

Issue #03...

Does calibration method to achieve an accuracy of about 0.1° require complicated work?

Then what is our solution…

It's as simple as rotating the shaft just three times.

An example of calibration is shown below. Click here for a demonstration video.

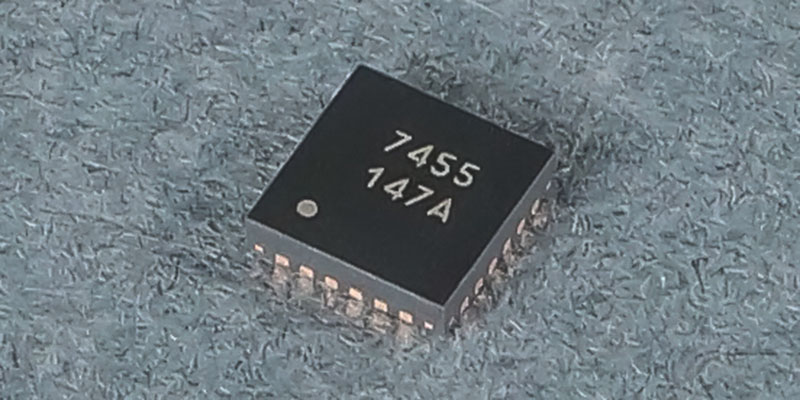

(The product used in the video is the AK7454, but you can use the AK7455 as well.)

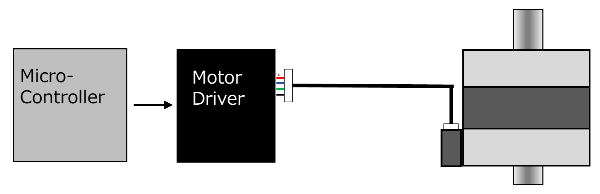

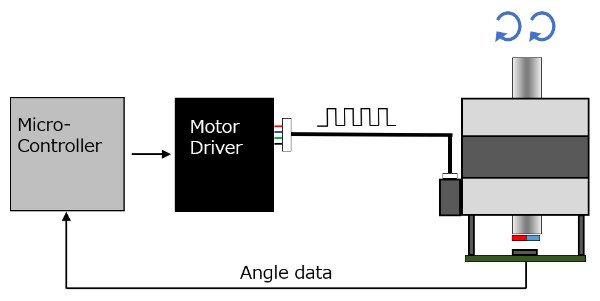

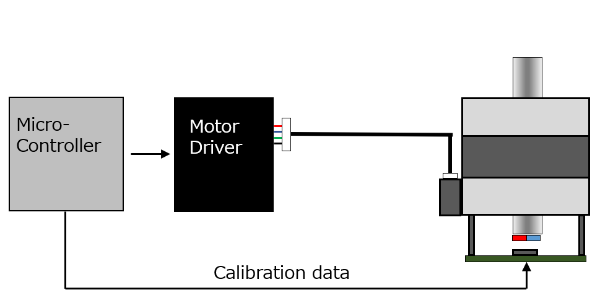

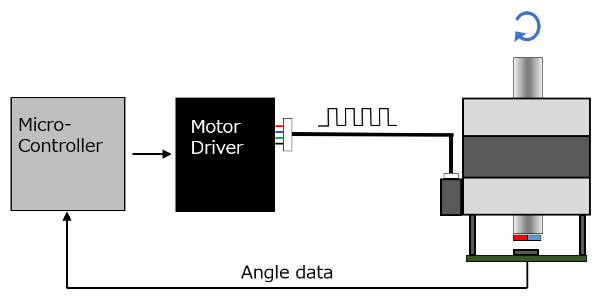

① What you need: motors, drivers, micro-controllers, magnets, and AK7455.

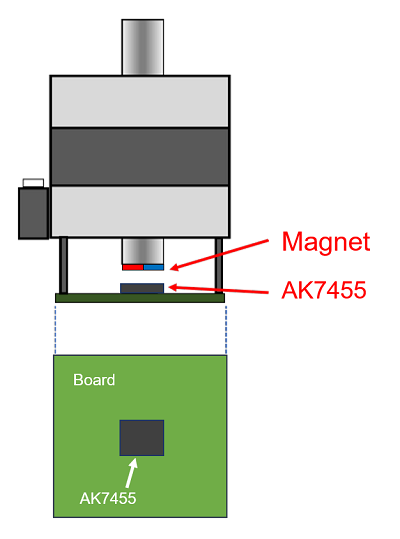

② Attach a magnet on the shaft and install the board with the AK7455 to the motor.

③ Rotate the shaft twice and acquire angle data, then create calibration data.

④ Write the calibration data to the AK7455.

⑤ Check the final accuracy by rotating the shaft once.

This is the end of calibration.

The above is an example of a stepper motor. If you consider using a DC brushless motor, please contact us.

The AK7455 can be used in two ways: Shaft-End and non-Shaft-End (Off-Axis) configuration. Calibration is performed in the same way for both Shaft-End and Off-Axis. As for the accuracy after calibration, it is possible to achieve an accuracy of about 0.1° as with Shaft-End, even with Off-Axis.

For Off-Axis, please refer to “Off-Axis configuration enhances the design flexibility”.

For more details, contact us with the inquiry form.