Currentier

"Currentier" is the brand name of AKM's coreless current sensor IC.

It is the coined word which comes from combination of "Current" and "Frontier".

* Currentier is a trademark of Asahi Kasei Microdevices Corporation.

Current Sensors

1. Overview : What is "Currentier" ?

"Currentier" is the brand name of AKM's coreless current sensor IC. It is the coined word which comes from combination of "Current" and "Frontier". Coreless current sensor has common advantage of small size.

Compared to the other general coreless current sensor ICs, Currentier has more attractive advantages: low-heat generation, high resolution, fast response, and high accuracy.

1. Reducing System size (substrate and equipment size)

- The board area for heat dissipation can be reduced because of ultra-low heat generation.

- Smaller IC size and fewer peripheral parts

- Downsizing peripheral parts because Currentier can support higher switching frequencies

2. Simplifying thermal design

Thermal design can be simplified because the primary conductor has low resistance and heat generation is very low.

3. Redusing design man-hours

Currentier supports a wide current measurement range of ±5 to 180App in the same packages.

It achieves standardization of parts and circuit substrates, and can reduce design man-hours.

4. Creating a safer system

- Creepage/Clearance distance of 8mm or more ( It is compliant with isolation properties which are defined in UL61800-5-1 )

- Available for 400V reinforced insulation

- Suitable for overcurrent detection with fast response ( 1us )

5. Improving system efficiency and providing more precise control

- Achieves the same level of high accuracy as a closed-loop and improves system efficiency

- High resolution can suppress vibration of servo motor and achieve more precise motor control

2. Hall element of Currentier

AKM's coreless current sensor IC has different specifications compared to general coreless current sensor ICs. It is because of AKM's hall elements with outstanding technical capabilities.

Both Si hall element and AKM's compound semiconductor hall element have the same role of "detecting magnetic field", but its performance is quite different. The "Hall effect", which indicates the output voltage of the hall element, is known to vary by a factor of several dozen depending on the materials. AKM is the manufacture in the hall element industry with a history of about 40 years and many patents. AKM has manufactured coreless current sensor IC with this high sensitive compound semiconductor Hall element.

Patent No.: US7723814

Patent No.: US8154280

Patent No.: US10429455 etc.

Currentier makes use of the characteristics of AKM's compound semiconductor hall elements in below two ways.

- High sensitivity hall element → Low-heat generation package → Supports large current

* For more details, please refer to "3. Packaging technology of Currentier"

- High sensitivity hall element → Wide signal bandwidth → Fast response

* For more details, please refer to "4. ASIC technology".

Representative products: CZ375 series, CZ372, CZ370 series, CZ3A series.

3. Packaging technology of Currentier

The package of Currentier has two features: large current capability and high insulation.

3-1. (Technology which achieves) low-heat generation and wide current range up to 180A

Low-heat generation and large current capability are achieved by AKM's packaging technology that utilizes high sensitive hall elements.

AKM's Hall element has about 30 times higher sensitivity than a general Si Hall element. Therefore, even if the magnetic field B generated by the measurement current I is small, the output signal is sufficient.

The magnetic field B can be small, the current density in the primary conductor can be reduced. Accordingly, the low resistance can be achieved by increasing the cross-sectional area of the primary conductor.

The CZ375, CZ372, CZ370 series has a low resistance of 0.27mΩ as the primary conductor resistance, which is 1/3 of other general coreless current sensor. As the heat generation is proportional to the primary conductor resistance, when the same amount of current is applied, the heat generation is also reduced to about 1/3 of that of general coreless current sensors. This is how Currentier achieves system downsizing.

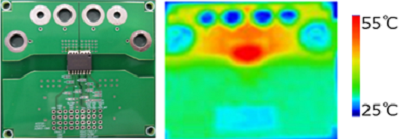

Figure 1 shows the heat generation result of CZ375, CZ372, CZ370 series, applied current 40A.

Figure 2 shows the heat generation result of general coreless current sensor, applied current 40A.

As a result of low heat generation , Currentier can be used even for large current.

Ficure 1. Heat generation result of CZ-37 series

Ficure 1. Heat generation result of CZ-37 series

Figure 2. Heat generation result of general coreless current sensor

Figure 2. Heat generation result of general coreless current sensor

With above technology, Currentier can support large current ( >100App ) to low current ( ±5App ) in the same package.

The same current sensor lineup can be used for products with different capacities, which reduces man-hours for design verification and part qualification.

3-2. (Technology which achieves) high insulation

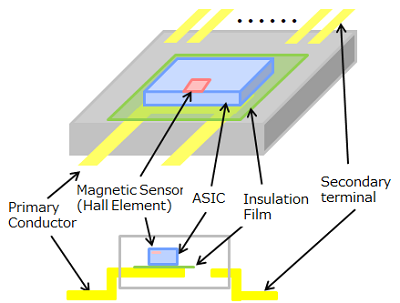

Secondly, the high insulation is achieved by its package structure. There are significant differences between Currentier and other general coreless current sensor ICs.

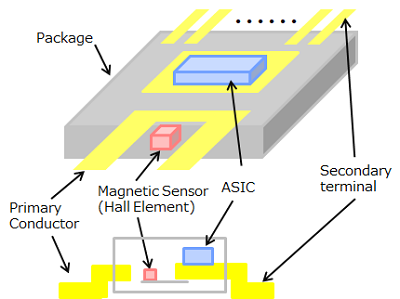

Figure 3 shows schematic of Currentier's package, and Figure 4 shows that of other general coreless current sensor ICs.

As for Currentier, the primary conductor ( high voltage side ) and the ASIC/hall element ( low voltage side ) are separated physically, and the space between them is filled with the package resin, an insulator. Because of this unique package structure, Currentier achieves high insulation without creepage inside the package.

In contrast, as for a general coreless current sensor IC, an insulation film is placed on the primary conductor ( high voltage side ) and the ASIC ( low voltage side ) is placed on top of it.

In this package structure, there is a creepage among the primary conductor, an insulation film and ASIC paths. Therefore, insulation breakdown is more likely to happen if there is a space gap between the insulation film and the package resin. This package structure needs to be checked for sufficient adhesion, considering age-related degradation.

Currentier achieves creepage and clearance distance of 8mm or more, and available for 400V reinforced insulation. AKM's unique packaging technology to secure insulation is because of our packaging and hall element technology, and it is also patented.

Patent No.: US10215781

Patent No.: US10101368 etc.

Figure 3. Schematic of Currentier's package (See through view / Cross sectional view)

Figure 3. Schematic of Currentier's package (See through view / Cross sectional view)

Figure 4. Schematic of general coreless current sensor's package (See through view / Cross sectional view)

Figure 4. Schematic of general coreless current sensor's package (See through view / Cross sectional view)

4. ASIC technology

The role of ASIC is the same for Currentier and other general coreless current sensor ICs: 1. amplification of magnetic sensor signals, 2. adjustment of current sensitivity, 3. adjustment of zero-current voltage, and 4. temperature compensation.

Currentier's ASIC has two significant advantages: fast response and high resolution.

Currentier's fast response is achieved by the specification of high sensitivity Hall element.

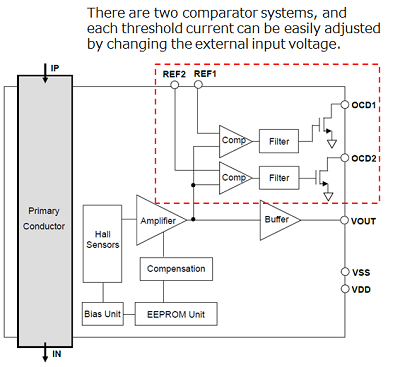

If the magnetic field intensity is the same, the more sensitive the Hall element is, the larger the hall element signal that applies to the ASIC becomes. Thus, the application factor of the amplifier in the ASIC can be low, and a wider signal bandwidth can be achieved. The wider the signal bandwidth is, the faster the current sensor responds. This advantage is suitable for applications which fast response is required, such as overcurrent detection. Some of AKM product series ( e.g., CZ3A series ) have comparator systems in the IC itself and do not require an external comparator, as you can see in the Figure 5.

Figure.5 Block diagram of CZ-3A series

Figure.5 Block diagram of CZ-3A series

As the next generation of power devices expands and the switching frequency becomes higher, the demand of Currentier's fast response will be increased.

Currentier achieves highly accurate compensation of various temperature characteristics by AKM's unique circuit technology, and also achieve high accuracy current detection which is comparable to closed-loop and shunt resistor + isolation amplifier. As a result of that, Currnetier can contribute to more efficient motor control, and thus it also contribute to improve system efficiency and precise control.

Patent No.: US9513348

Patent No.: US9535139 etc.

5. Summary

General coreless current sensor ICs have the following advantages: low-heating, detecting both AC and DC current, no magnetic hysteresis, and no need for isolated power supply on the primary side. But at the same time, there are also disadvantages: low resolution and late response time.

Currentier overcomes above disadvantages by combination of AKM's unique technology of high sensitivity compound semiconductor hall element, packaging and ASIC. Currentier is the coreless current sensor IC that possesses attractive advantages: ultra-low heating, high resolution, fast response and high accuracy.

Recommend

If you would like to know more about how Currentier can solve problems, please click below links.

Solutions

If you would like to know more about how Currentier can solve problems, please click below links.

Improving System Efficiency and Providing More Precise Control

Applications

If you would like to consider proper products from application examples, please click below links.

Products

For more detailed information about each product series, and for selection of specific products, please click below links.