Creating a safer system

In this page #3, we would like to explain how Currentier can contribute to "Creating a safer system".

Current Sensors

Many control devices, such as general-purpose inverters for controlling motors, AC servo motor drivers for precise position control, and controllers for robots to automate operations, mainly operate at 200V or 400V systems. Therefore, it is necessary to be firmly isolated between a high voltage primary side and a low voltage secondary side where the controller is placed. In addition to isolation, overcurrent detection is important for realizing a safer system. It is because a trade-off with the efficiency of control devices (reduction of on-resistance of IGBT) is so-called "short-circuit tolerance" of IGBT. Therefore, in order to achieve a high efficiency in a system, it is necessary to shut down the system firmly in a shorter time when an overcurrent flows. Besides, there has been an increasing need for industrial equipment using in bad environment where liquid and dusts are existed.

Currentier contributes to "creating a safer system" by following three advantages:

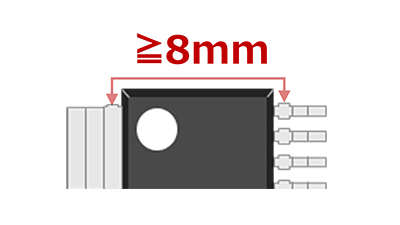

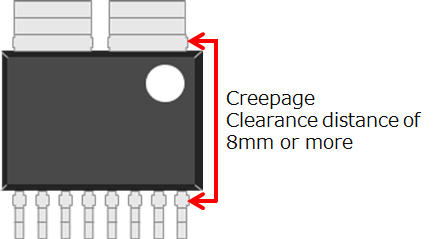

- Creepage/clearance distance of 8mm or more

- Fast response and overcurrent detection function

- Improved sealing and fan-less equipment due to low heat generation

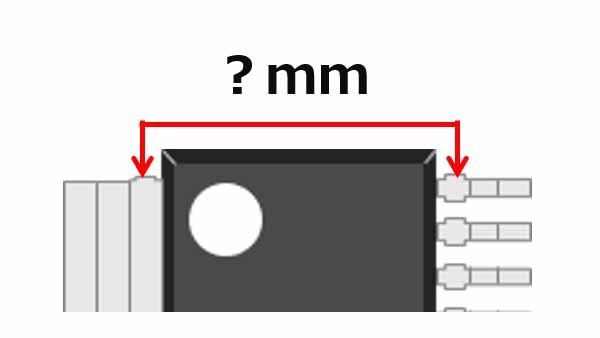

1. Cleepage / Clearance distance of 8mm or more

There are some standards established by certification bodies such as UL and IEC as criteria for isolation. For example, industrial equipment in North America, systems must achieve isolation that complies with UL61800-5-1. As an index to cope with that, it is necessary to keep creepage and clearance distance of isolation elements such as current sensors and photocouplers above a certain value. For instance, in order to support a 400V system under certain conditions, it is necessary to maintain a creepage /clearance distance of 8mm or more.

In order to meet these requirements, the following issues are existed.

Issue 1:

The current sensor that can secure creepage/clearance distance of 8mm or more has only existed in cored current sensors and current transducers, which increases size and cost.

(More details, click #01 System Downsizing)

Issue 2:

When using an isolation amplifier, the number of peripheral parts may increase, which increases the total cost and the size of substrates.

(More details, click #01 System Downsizing)

Issue 3:

When using an isolation amplifier, heat dissipation area due to heat generation of the shunt resistor is increased and thus design man-hours are increased.

(More details, click #02 Reducing design man-hours)

Currentier is current sensor IC to achieve creepage and clearance distance of 8mm or more, and is certified with UL/IEC62368-1 and UL1577 (Figure 1). Currentier can solve above problems of size, cost and design man-hours while achieving high insulation. As a result, it has been adopted in industrial equipment all over the world.

Figure1. Creepage/clearance distance of CZ-37 series

Figure1. Creepage/clearance distance of CZ-37 series

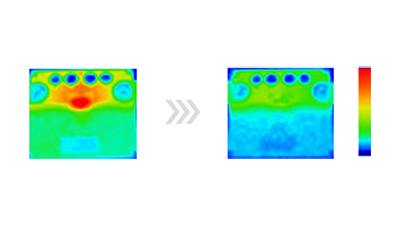

2. Fast response and overcurrent detection function

In addition to isolation, fast response and overcurrent detection function on high voltage side are other key factors for achieving a safer system.

1. Fast response

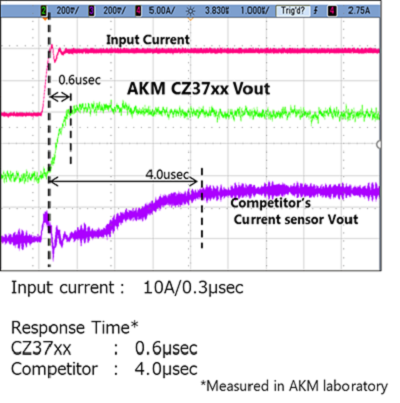

Insulated Gate Bipolar Transistor (IGBT) for inverter control is currently being developed and higher efficiency is processing. In general, a trade-off with this efficiency is the so-called "short-circuit tolerance". Therefore, in order to achieve a high efficiency in a system, it is necessary to shut down the system firmly in a shorter time when an overcurrent flows. Especially SiC/GaN which is the next generation of power devices driven at high frequencies, the system must be shut down in a shorter time, therefore Currentier's fast response can be a key factor.

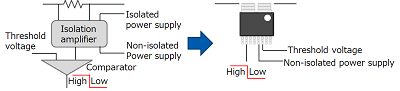

For example, in the case of overcurrent detection at phase current, the system is required to be designed with a sufficient margin to prevent breaking down the system by predicting when overcurrent would likely to flow in. It is because the response time is not fast enough with the conventional shunt resistor + isolation amplifier + comparator method. As a result, the system can be stopped at unnecessary timing or designed with components that have a large capacity.

Currentier applies AKM's ultra-high sensitivity compound hall element technology to achieve a response time of 1usec (typ.) and it can detect overcurrent directly without prediction (Figure 2. Measurement data at N=1 is 0.6usec). Therefore, Currentier can reduce system downtime and enable the use of appropriate capacity components, and thus it contributes to a safer system while achieving system downsizing and reducing cost (Figure 3).

Figure2. Response time comparison of CZ-37 series and competitor

Figure2. Response time comparison of CZ-37 series and competitor

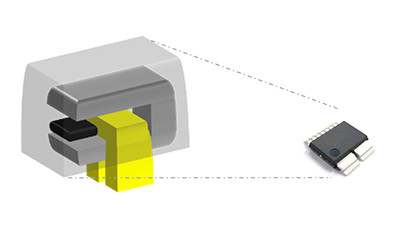

2. Overcurrent detection on high voltage side

As for Currentier, the primary conductor (high voltage side) and the ASIC/hall element (low voltage side) are separated physically, and creepage/clearance distance of 8mm are secured. Therefore, it can be mounted on the high voltage side while ensuring safety.

There are some IPMs with overcurrent detection function, but they detect on the low voltage side of the circuit, which may occur unprotected circuit depending on the path. Currentier has an advantage that can make the system safer by mounting on high voltage side.

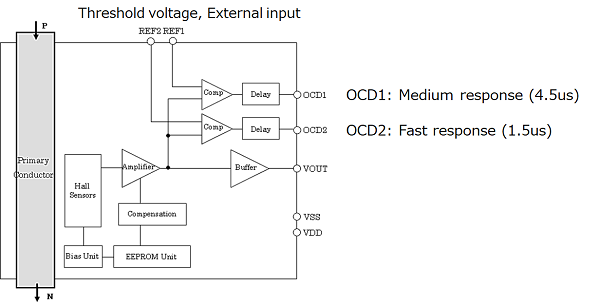

The CZ3A series is built in dual overcurrent detection with adjustable thresholds. It makes possible to detect both overcurrent and current for torque control by mounting Currentier on phase current while reducing the number of peripheral components (Figure 4).

Figure 3. Block diagram of overcurrent detection (left: with isolation amplifier, right: currentier)

Figure 3. Block diagram of overcurrent detection (left: with isolation amplifier, right: currentier)

Figure 4. Block diagram of CZ-3A0x series

Figure 4. Block diagram of CZ-3A0x series

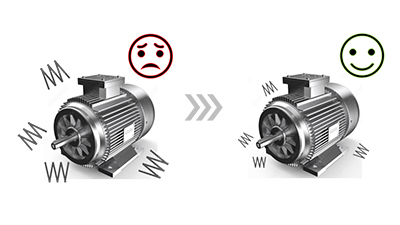

3. Improved sealing and fan-less equipment due to low heat generation

Recently, there has been an increasing need for using industrial equipment more safely and with a lower failure rate even in bad environment where liquid and dusts are existed.

For example, more and more food factories have introduced robots, and it's necessary to take care about foreign matter contamination and hygiene measures. Therefore, in some cases, the robots are produced to be splash proof and washable. In one case, in order to meet IP*5 standards for protection against liquid and dust, the products must withstand 12.5L/min of flowing water from all directions for 3 minutes. Therefore, the equipment must be well sealed to prevent water flowing in. Besides, in order to meet IP*5 of dust protection, the equipment must be fanless and the amount of dust flying in the equipment must be kept below a certain level.

It is possible to increase the airtightness of equipment and make it fanless because the primary conductor of Currentier is low resistance and low heat-generation (*1). As a result, Currentier can contribute to the acquisition of higher IP standards and the development of high value-added products.

(*1 : For more details, click #01 System Downsizing)

Figure 5. IP code

Figure 5. IP code

Summary

AKM's coreless current sensor IC Currentier contributes to "Creating a safer system" by

- UL61800-5-1 compliant, creepage/clearance distance of 8mm or more

- Fast response and overcurrent detection function

- Higher IP standards due to improved sealing and fan-less equipment

On the following pages you will find "Creepage / Clearance distance Calculation tool" in accordance with UL61800-5-1. You can tailor the simulation to your requirements.

(You will need to register with MyAKM to use this tool.)

Recommend

Solutions

If you would like to know more about how Currentier can solve problems, please click below links.

Applications

If you would like to consider proper products from application examples, please click below links.

Products

For more detailed information about each product series, and for selection of specific products, please click below links.