What is a coreless current sensor ?

Current sensor is a device that the current to be measured generates a magnetic field around the current path, and by detecting this generated magnetic field using a magnetic sensor, the amount of the current can be measured.

"Coreless current sensor" is one of the current sensor types, without a magnetic core.

Current Sensors

1. Overview: What is a coreless current sensor ?

This page explains what a coreless current sensor IC is with its principles and features. With understanding of its principles and features, you can understand more deeply about how to use and its advantages.

(Currentier, which is the brand name of AKM's coreless current sensor IC, has its unique features and it is featured on the link "Currentier is...".)

A current sensor is the device that generates a signal proportional to the amount of current using the output of a magnetic sensor that detects the current flowing through the board and wiring. A Coreless current sensor is one of the current sensor types, without a magnetic core. Other current detecting methods, such as a cored current sensor, are explained in more detail in the link "Types and Characteristics of Current Sensors".

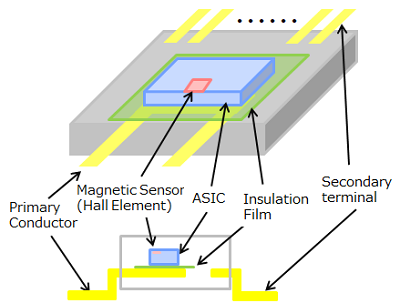

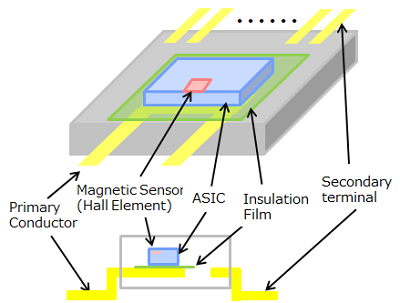

Figure 1. is the schematic of general coreless current sensor IC's package. Coreless current sensor IC consists of below three components:

1. Package (including the primary conductor)

2. Magnetic sensor (mainly hall element)

3. ASIC

Coreless current sensor IC has a very simple configuration; magnetic sensor detects the magnetic field generated by the measured current flowing through the primary conductor, and ASIC corrects and amplifies signals from magnetic sensors. In the later of this page, we would like to explain about the role of these three components in more details.

Figure1. Schematic of general coreless current sensor's package (See through view / Cross sectional view)

Figure1. Schematic of general coreless current sensor's package (See through view / Cross sectional view)

2. The Role of Package

The role of the package in coreless current sensor IC is 1. generation of a magnetic field and 2. ensure insulation.

2-1. Generation of a magnetic field

The primary conductor is involved in the generation of a magnetic field. The primary conductor is the path of measurement current and has a role of magnetic field generator. The measurement current flows into the primary conductor from the printed circuit board and generates a magnetic field B around the primary conductor in proportion to the current amount. The primary conductor is made of the package lead frame as it is.

Shunt resistor + isolation amplifier / isolation ADC is another main current sensing method which is commonly used, but this method has a disadvantage that thermal design is difficult. This is because this method is based on I to V conversion, and the resistance R needs to be large enough to ensure the output voltage V.

In contrast, as for coreless current sensor IC, the primary conductor is just the path of the measured current, and the resistance R can be sufficiently small because the primary conductor only needs to create a magnetic field. Coreless current sensor IC with a small resistance value R generates less heat because the power P is proportional to the resistance R. As a result of low-heat generation, the system downsizing ( reducing size of substrate and equipment ) can be achieved.

As explained above, coreless current sensor IC is low-heating, but AKM's coreless current sensor Currentier is excellent because the resistance value of its primary conductor is very small and it suppresses heating. For more details, please click "Currentier is...?".

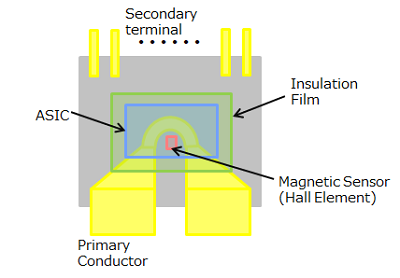

Figure 2. Schematic of general coreless current sensor's package (See through view / Cross sectional view)

Figure 2. Schematic of general coreless current sensor's package (See through view / Cross sectional view)

2-2. Assurance of insulation

Coreless current sensor ICs have another advantage that it's easy to ensure insulation. Figure 2 shows the schematic of general coreless current sensor's package (See through view / Cross sectional view).

Inside the package of a general coreless current sensor IC, an insulation film is placed on the primary conductor and the ASIC is placed on top of it. And outside the package, the specified insulation performance is achieved by allocating the creepage and clearance distance between the the primary conductor and the secondary terminal.

*Comparing internal structure, there are significant differences between Currentier and other general coreless current sensor ICs. The link "Currentier is...?" explains about the differences and its effects in detail.

3. The Role of Magnetic Sensor

A magnetic sensor has its role to measure magnetic field which is generated from the primary conductor. Hall elements are mainly used as magnetic sensors, which use hall effect and output a voltage proportional to the magnetic fields. The magnetic field generated by the flowing current through the primary conductor is proportional to the current. Therefore, the output of the hall element and the flowing current through the primary conductor is also proportional.

The hall element reacts to magnetic field and is not connected, so that it can ensure insulation between the primary conductor ( high voltage side ) and the output of the current sensor.

General coreless current sensor ICs ensure insulation by insulation film, as explained in 2-2. There are two types of hall element, Si hall element and compound semiconductor hall element. Other than AKM, hall element is put inside ASIC and is made of Si. The hall effect depends on the electron mobility of the hall element material, and Si is about 1450 ( cm2/Vs ). This value is considerably smaller than the electron mobility of InAs ( Currentirer uses InAs ), which is about 1/24 of that of Si hall element, and this causes a problem in terms of resolution (Table 1).

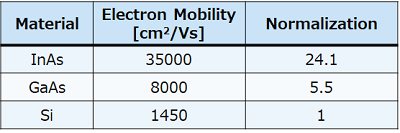

Table 1. Material of hall element and electron mobility

Table 1. Material of hall element and electron mobility

The magnetic field generated by current can be measured by direct current (DC) or alternate current (AC) because it is generated at the same absolute value. The ability to measure DC differs from electromagnetic induction methods such as current transformer (CT).

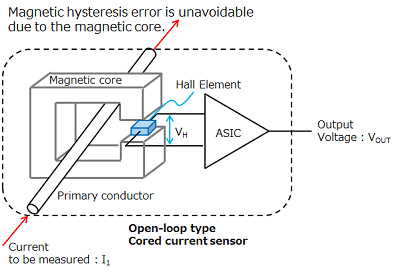

Besides, there is no magnetic hysteresis in principle because there is no magnetic core like cored current sensors. ( Figure 3. ) Therefore, highly accurate and reproducible measurement are possible even in the vicinity of zero current.

Figure 3. Structural picture of cored current sensor (Open-loop type)

Figure 3. Structural picture of cored current sensor (Open-loop type)

Not only with hall element, but also there are coreless current sensor ICs with magnetoresistive element ( MR ) in the market. However, MR is considered unsuitable magnetic sensor for current sensor. It is because of following concerns:

- Irreversibly changing characteristics after large current applied ( caused by the magnetic field generated from large current )

- Deterioration in linearity around zero current ( caused by Barkhausen effect*1 )

- Magnetic hysteresis

- Magnetic field effects from outside

As a result, the characteristics of MR ( current sensitivity and offset ) change when overcurrent is applied and MR is not as accurate as current sensor with hall element.

*1 Barkhausen effect

A phenomenon in which noise is generated due to the discontinuous movement of magnetic field walls caused by magnetic field. For current sensor, the noise is generated near zero current, where magnetic field is weak, and it makes linearity deteriorated.

4. The Role of ASIC

ASIC's function is 1. amplification of magnetic sensor signals, 2. adjustment of current sensitivity, 3. adjustment of zero-current voltage, and 4. temperature compensation.

Thanks to ASIC, coreless current sensor IC is an easy-to-use product with less impacts of temperature characteristics.

In addition, there is no need for isolated power supply on the primary side, which is a big advantage of coreless current sensor ICs in terms of design and layout.

5. Summary

As explained, coreless current sensor IC has a very simple configuration.

Magnetic sensor detects the magnetic field created by the measured current flowing through the primary conductor, and IC corrects and amplifies signals from magnetic sensors.

Coreless current sensor ICs have the following advantages:

- low-heating

- detecting both AC and DC current

- no magnetic hysteresis

- no need for isolated power supply on the primary side

But at the same time, there are also disadvantages:

- low resolution

- late response time

AKM's coreless current sensor IC "Currentier" is the one which overcomes above disadvantages.

Recommend

Please refer to the below links for more details about the characteristics of AKM coreless current sensor IC "Currentier".

AKM coreless current sensor IC "Currentier"

Small package and system downsizing by low-heat generation

Board commonality with wide current measurement range and simplification of thermal design by low-heat generation

Standards of insulation (UL compliant/certified) and over current detection function

System efficiency by accuracy, low noise characteristics, and good temperature characteristic