Improving System Efficiency and Providing More Precise Control

In this page#4, we would like to explain how Currentier can contribute to "Improving system efficiency and providing more precise control".

Current Sensors

In recent years, as factory automation (FA) proceeding, many control devices such as general inverters, AC servo motor drives, and controllers for robots have been installed in factories and other facilities. For such control devices, there are requirements for finer processing and further energy savings to reduce production costs. In order to achieve these requirements, it is necessary to improve the control performance of the motor and bring the motor rotation closer to the ideal state.

Currentier can contribute to improving system efficiency and providing more precise control by following three reasons:

- Improving torque control performance

- Low vibration motors

- Improving system efficiency

1. Improving torque control performance

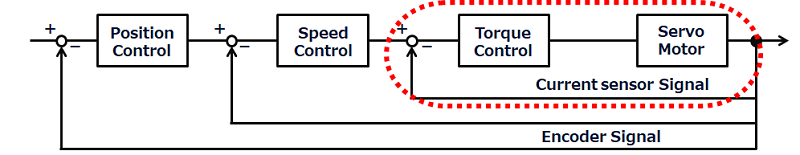

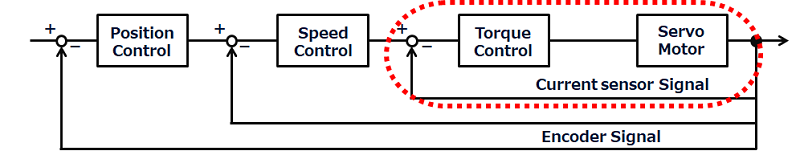

Figure 1 shows the block diagram of a servo motor. A servo motor feeds back signals of current sensor and encoder to control torque, speed and position. The signal of current sensor is used for torque control.

Figure 1. Block diagram of a servo motor

Figure 1. Block diagram of a servo motor

The specifications of current sensors that contribute to the torque control performance include below:

- offset accuracy

- current sensitivity accuracy

- noise

Compared to other coreless current sensor ICs, Currentier has better accuracy in each aspect.

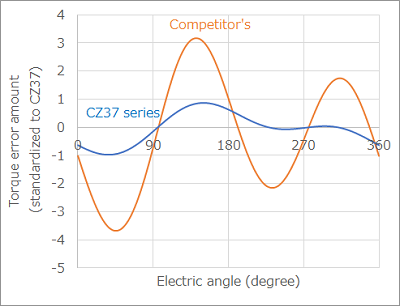

Figure 2 shows the result of calculating how this specification difference appears as a torque error. The calculated system uses a coreless current sensor IC as the phase current control of the inverter and is assumed to be used in two-phase current detection.

Orange : Competitor's coreless current sensor IC

Blue : Currentier CZ375, CZ372, CZ370 series

The horizontal axis is the electrical angle and the vertical axis is the amount of torque error (standardized to CZ37), assuming an ideal system with no errors except for the offset and current sensitivity error of the current sensor IC itself.

As it can be seen from Figure 2, the error of the coreless current sensor IC is directly related to the torque error, and selecting a current sensor with high accuracy and a small error will lead to improve torque control performance.

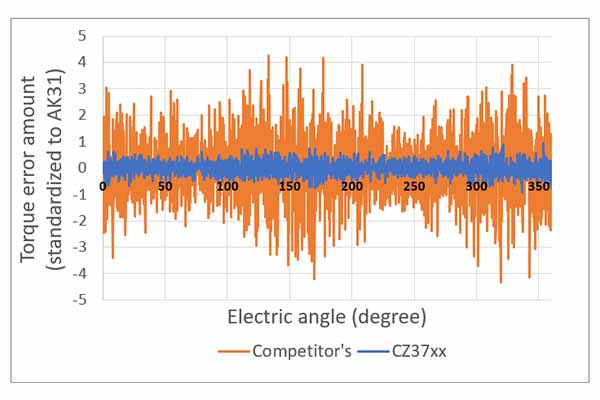

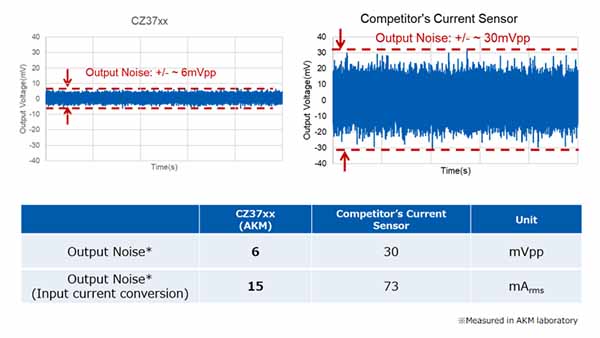

In addition, there is a significant influence on torque error caused by the noise. Figure 3 shows how much the amount of torque can be influenced by the noise of CZ375, CZ372, CZ370 series and competitor's coreless current sensor IC. As in Figure 2, it is calculated in the system of two phase current detection of the inverter, assuming an ideal system with no errors except for the noise of the current sensor. As the results show, it can be controlled with a much smaller torque error than other products by using CZ375, CZ372, CZ370 series.

Figure 2. Influence of current sensitivity error to torque error

Figure 2. Influence of current sensitivity error to torque error

Figure 3. Influence on torque error caused by current detection noise (Blue: CZ375, CZ372, CZ370 series, Orange: Competitor's coreless current sensor)

Figure 3. Influence on torque error caused by current detection noise (Blue: CZ375, CZ372, CZ370 series, Orange: Competitor's coreless current sensor)

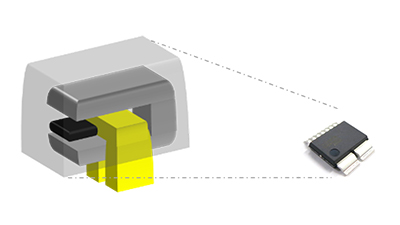

As for AC servo motor controls, the shunt + isolated ADC method has been more widely used than the coreless current sensor IC. It is because the adoption of conventional current sensors has been limited due to their insufficient current detection accuracy compared to the shunt method.

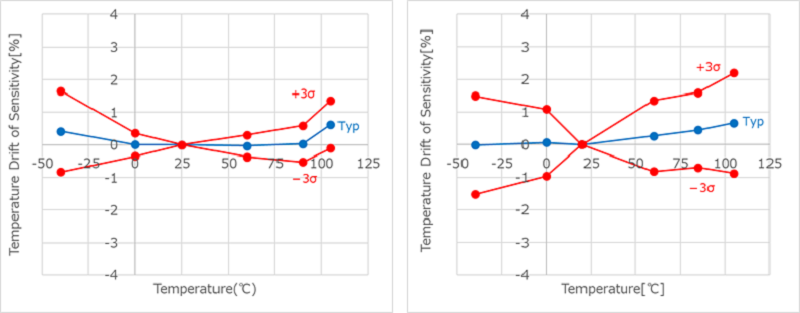

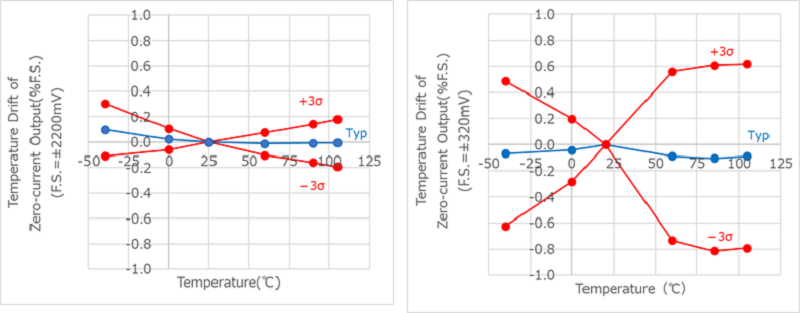

However, Currentier has been increasingly replacing shunt method because it can achieve the same or better performance than shunt method (Figure 4&5) while achieving system down-sizing.

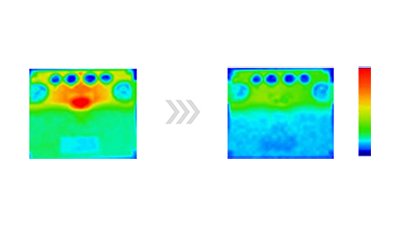

Figure 4. Specification comparison with shunt method (Current sensitivity temperature drift, left:CZ375, CZ372, CZ370 series, right: competitor's "shunt+isolation ADC")

Figure 4. Specification comparison with shunt method (Current sensitivity temperature drift, left:CZ375, CZ372, CZ370 series, right: competitor's "shunt+isolation ADC")

Figure 5. Specification comparison with shunt method (Offset temperature drift, left:CZ375, CZ372, CZ370 series, right: competitor's "shunt+isolation ADC)

Figure 5. Specification comparison with shunt method (Offset temperature drift, left:CZ375, CZ372, CZ370 series, right: competitor's "shunt+isolation ADC)

2. Low vibration motors

Current sensor is used for torque control as already explained in section 1. However, feedback circuits affect position and speed control as well because it operates at the highest frequency.

Same as Figure 1: Block diagram of a servo motor

Same as Figure 1: Block diagram of a servo motor

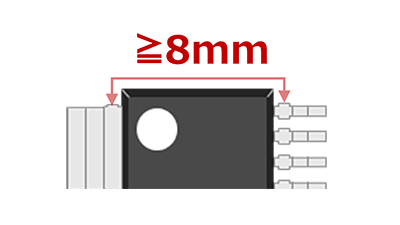

Particularly in the field of AC servo motors which high-end encoders (24bit) are used, the resolution of current sensor is mostly insufficient to match the resolution of encoder. In such cases, by using Currentier which detects the current with high-resolution, not only noise in torque control but also in speed and position control can be reduced. As a result, it achieves low motor vibration. CZ375, CZ372, CZ370 series is the coreless current IC that can provide significantly high-resolution and its specifications are nearly 5 times better than those of competitors. (Figure 6)

Figure 6. Noise characteristics comparison between CZ375, CZ372, CZ370 series and competitor's current sensor

Figure 6. Noise characteristics comparison between CZ375, CZ372, CZ370 series and competitor's current sensor

3. Improving system efficiency

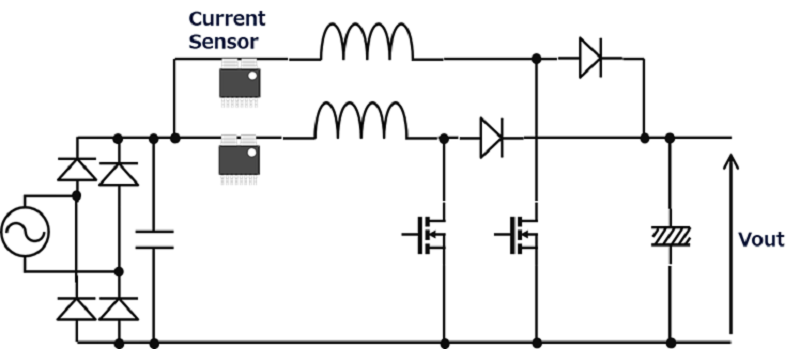

In recent years, with increasing interest in the environment, improving the efficiency of industrial and residential equipment has become a major issue. Thus, an attention has been paid to the power-factor correction (PFC) circuit. In the past, control ICs for PFCs were widely used, but recently, circuit composed of discrete components such as interleaved PFCs (Figure 7) have been adopted in order to achieve even higher power factor and higher efficiency as well as downsizing. For example, in multi air conditioners, commercial air conditioners and room air conditioners, SEER (Seasonal Energy Efficient Ratio) is regarded as important. To improve SEER, new development of the above PFC circuit is underway.

The higher power factor and the higher efficiency can be made possible by a newly developed PFC circuit method and high accuracy current detection. On the other hand, for system downsizing, it is necessary to increase carrier frequency. (By increasing carrier frequency, L and C in the Figure 7 can be small (*2). Thus, to achieve high power factor, high efficiency and system downsizing all together, a current sensor with high accuracy and fast response is needed.

AKM's coreless current sensor "Currentier" features both high accuracy and fast response, which is ideal for PFCs in power supplies for air conditioners and other applications.

Figure7. Interleaving PFC and current sensor

Figure7. Interleaving PFC and current sensor

(*2) refer to #01 System Downsizing.

Summary

AKM's coreless current sensor IC Currentier contributes to "Improving system efficiency and providing more precise control" by

- Improving torque control performance

- Low vibration motors

- Improving system efficiency

We have prepared a tool for simple simulation of servo motor torque error. You can experience the low noise and high accuracy of AKM's current sensor. You can also compare it with the current detection method that you are currently using.

Recommend

Solutions

If you would like to know more about how Currentier can solve problems, please click below links.

Applications

If you would like to consider proper products from application examples, please click below links.

Products

For more detailed information about each product series, and for selection of specific products, please click below links.