Coreless current sensor IC

Thermal Simulation Tool

Current Sensors

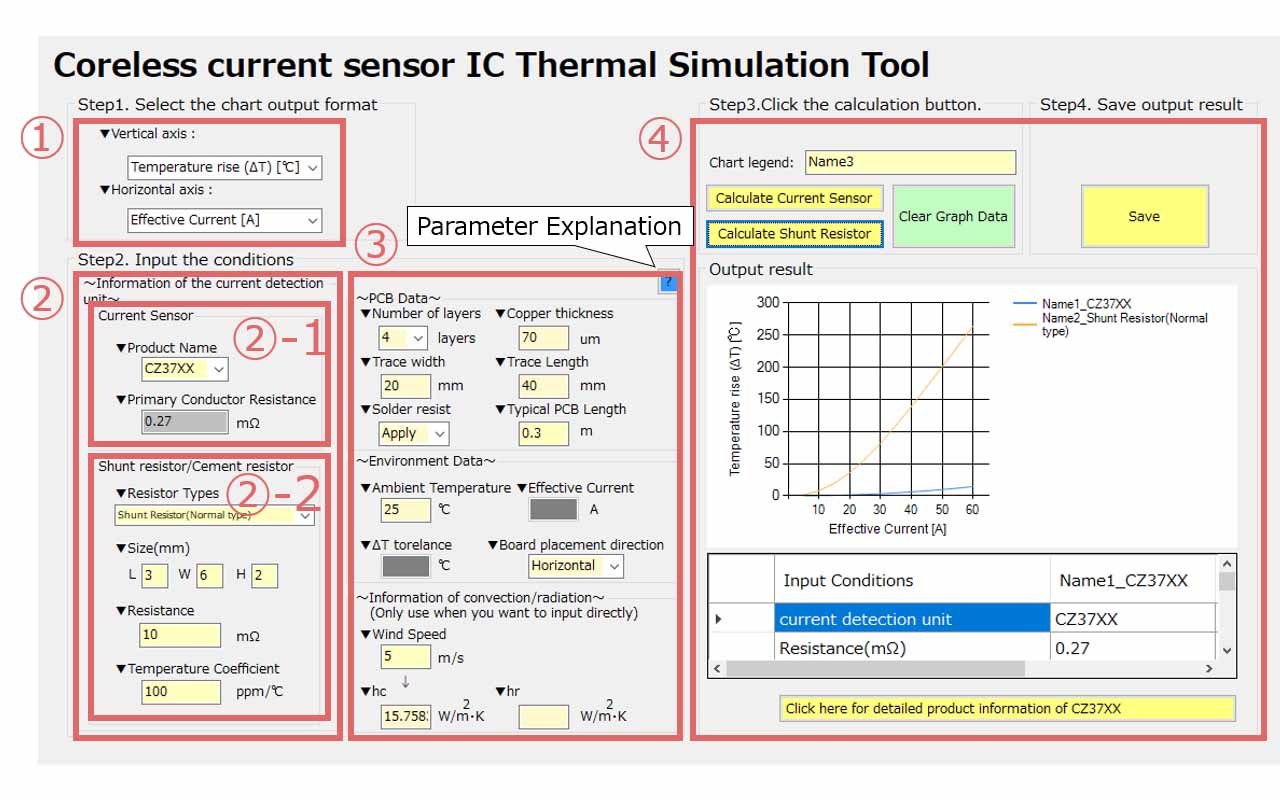

This page introduces a tool that allows you to compare the heat generation of AKM's coreless current sensor IC "Currentier" with shunt resistors and cement resistors.

By entering the information of your current shunt resistor/cement resistor and board information, you can relatively simulate how much the heat generation can be reduced by replacing them with the Currentier.

How to use the tool

"Coreless current sensor IC Thermal Simulation Tool" is a tool that can compare the surface temperature of our current sensors IC "Currentier" with a general shunt resistor at any current value or board condition.

You can choose high heat dissipation type or a normal type for the shunt resistor.

The simulation results do not guarantee absolute values. This tool can correctly compare the surface temperature rise of the shunt resistance and AKM's current sensor IC in relative terms.

Follow the 4 steps indicated below for the comparison.

① Select the chart output format

Vertical axis: Temperature rise ΔT

Horizontal axis: Current value and PCB conditions (selectable)

② Input the information of the current detection unit.

This tool can output a surface temperature of a single unit as well as the comparison of the surface temperatures between the current sensor and the shunt resistor.

②-1 Select a current sensor to be compared.

When a current sensor is selected, the primary conductor resistance value is automatically displayed.

*If you wish to enter a specific resistance value for calculation, register the data within myAKM.

②-2 Enter the information of the shunt resistor/cement resistor to be compared.

Mandatory items: Type / Size (mm) / Resistance value (mΩ)

Optional item: Resistance temperature coefficient

*If no information is input, 0ppm is used for calculation.

③ Enter PCB data and environment data

Mandatory items

Number of layers / Copper thickness / Wiring width/Wiring length / PCB surface condition / Board placement direction / Typical PCB length / Ambient temperature / Effective current

*Typical PCB Length

Placing the PCB horizontally: Short side length of the PCB

Placing vertically: Vertical board height

*The parameter that was selected as a horizontal axis in ① cannot be input.

Optional items

Wind Speed / Convection Heat Transfer Coefficient (hc) / Radiative Heat Transfer Coefficient (hr)

*If not selected, natural convention is used for calculation.

④ Performing calculations

"Calculate Current Sensor" button

"Calculate Shunt Resistor" button

When either of the buttons is pressed, a calculation result is output according to the information entered in Steps from 1 to 3.

*You can change the legend name arbitrarily.

*Unless the "Clear Graph Data" button is pressed, you can display up to five results with changed conditions by overlapping each other.

Press the "Save" button to save the output results.

This tool should be used on your PC.

What advantages are available for a current sensor of low heat generation?

As shown in the simulations, AKM's current sensor has a very low heat generation feature. What are the advantages of current sensor of low heat generation?

1. Contributing to system downsizing

A current sensor of low heat generation can contribute to system downsizing. If the heat generated from a current sensor becomes an issue, an extra space or component is required for heat dissipation. However, a current sensor of low heat generation does not require such consideration, enabling system downsizing.

2. Contributing to reduction of design man-hours

A current sensor of low heat generation contributes to reduction of design man-hours. If the heat generated from a current sensor becomes an issue, some measures are necessary in the design regarding the heat issue. However, a current sensor of low heat generation does not require such measures, enabling significant reduction of design man-hours.

3. Contributing to the configuring of safer system

A current sensor of low heat generation contributes to the configuration of safer systems. If the heat generated from a current sensor becomes an issue, installation of a fan or ventilation holes is necessary for heat dissipation. A current sensor of low heat generation does not require such features, thereby improving the airtightness of the equipment or eliminating the need for fan installation. This achieves acquisition of higher IP standards (waterproof and dustproof standards) and increases the added value of your products.

For further details, please access this link.