Solutions

Advantage of Currentier

Examples of Problem Solving for Control Equipment

Current Sensors

Currentiers generate less heat, have wide current sensing ranges, and have excellent high-speed response, insulation, accuracy, and resolution. Thanks to these features, not only can they detect currents with high accuracy, but they can also help solve various problems faced by control equipment.

This page consists of four sections: #1 System miniaturization, #2 Reduction of design man-hours, #3 Creation of safer systems, and #4 System efficiency improvement. Each section explains the value that Currentiers provide.

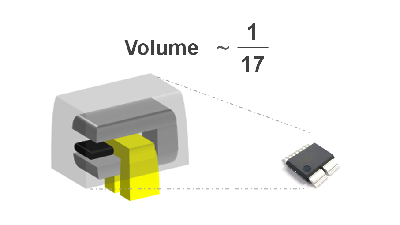

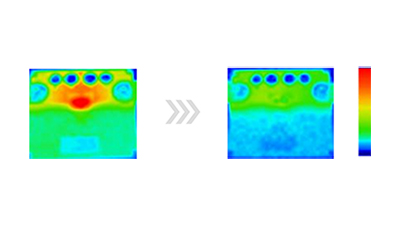

#01 System Downsizing

Currentier can contribute to system downsizing by three reasons:

- Low Heat

- Less Peripheral Parts and Smaller Package Size

- Speeding up Carrier Frequency

#02 Reducing Design Man-hours

Currentier can contribute to reducing design man-hours by following five reasons:

- Low Heat generation

- Supporting a wide current measurement range

- No need for isolated power supply on the primary side

- Excellent temperature characteristics

- No need to set up a new test environment

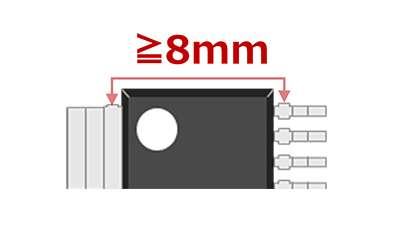

#03 Creating a Safer System

Currentier contributes to "creating a safer system" by following three advantages:

- Creepage/clearance distance of 8mm or more

- Fast response and overcurrent detection function

- Improved sealing and fan-less equipment due to low heat generation

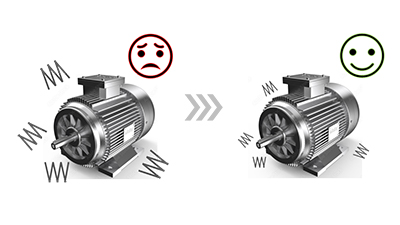

#04 Improving System Efficiency and Providing More Precise Control

Currentier can contribute to improving system efficiency and providing more precise control by following three reasons:

- Improving torque control performance

- Low vibration motors

- Improving system efficiency